loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

3 月 . 07, 2025 06:38

Back to list

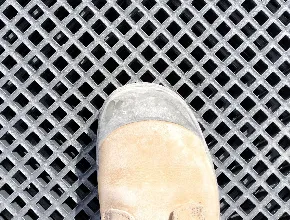

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

In the intricate world of plumbing and sanitation, floor drain gratings often play a silent yet crucial role. These otherwise unassuming components can significantly impact both the functionality and safety of various spaces, from commercial kitchens to residential basements. Understanding the nuances of floor drain gratings not only enhances system efficiency but also ensures compliance with sanitation standards.

Purchasing decisions should also consider the maintenance needs of the chosen grating. Ease of cleaning is critical for floor drain gratings situated in environments where sanitation is a priority. Removable components that allow for straightforward access to the underlying drain can greatly simplify upkeep, reducing the risk of clogs and maintaining a clean and safe environment. Moreover, advanced models now incorporate additional features such as anti-slip surfaces and anti-microbial finishes, pushing the boundaries of what traditional floor drain gratings offer. These innovations not only enhance safety but also align with growing demands for products that contribute to overall health and sustainability. Trust in reputable manufacturers with a proven track record becomes an indispensable factor. Leading brands often provide comprehensive warranties and professional support, a testament to their confidence in product quality and longevity. Partnering with these industry leaders imbues a sense of security and reliability, reinforcing the integrity of the sanitary systems they support. Ultimately, floor drain gratings exemplify how a nuanced approach to selecting and maintaining these components can transform basic functionality into a well-executed element of building design. Gratings that blend expert engineering with practical utility tackle immediate drainage needs while offering long-term benefits, underscoring their sustained relevance in contemporary architecture.

Purchasing decisions should also consider the maintenance needs of the chosen grating. Ease of cleaning is critical for floor drain gratings situated in environments where sanitation is a priority. Removable components that allow for straightforward access to the underlying drain can greatly simplify upkeep, reducing the risk of clogs and maintaining a clean and safe environment. Moreover, advanced models now incorporate additional features such as anti-slip surfaces and anti-microbial finishes, pushing the boundaries of what traditional floor drain gratings offer. These innovations not only enhance safety but also align with growing demands for products that contribute to overall health and sustainability. Trust in reputable manufacturers with a proven track record becomes an indispensable factor. Leading brands often provide comprehensive warranties and professional support, a testament to their confidence in product quality and longevity. Partnering with these industry leaders imbues a sense of security and reliability, reinforcing the integrity of the sanitary systems they support. Ultimately, floor drain gratings exemplify how a nuanced approach to selecting and maintaining these components can transform basic functionality into a well-executed element of building design. Gratings that blend expert engineering with practical utility tackle immediate drainage needs while offering long-term benefits, underscoring their sustained relevance in contemporary architecture.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024