loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 12, 2025 09:28

Back to list

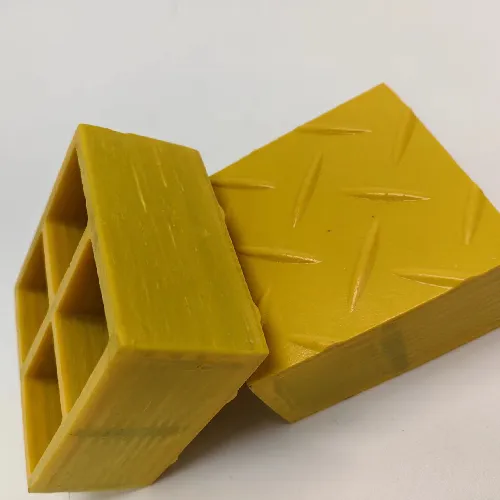

frp grating price

Navigating the complex world of floor grating pricing requires a nuanced understanding of various influential factors such as material choice, manufacturing processes, and the intended application environment. With years of experience in the industrial materials sector, the insights shared here aim to illuminate the comprehensive elements that affect cost while reinforcing value through quality and functionality.

The cost of transportation and installation should not be overlooked when considering floor grating pricing. Heavy and bulky materials like steel add substantial shipping costs, which may vary depending on the distance from manufacturer to installation site. Installations in challenging environments or remote locations might necessitate specialized equipment or labor, further influencing the overall cost. In addition to these factors, regulatory standards and certifications, such as ISO certifications for quality management and environmental standards, play a pivotal role. Products that comply with higher industry standards often command premium prices due to their guaranteed performance and safety assurances. Establishing trust with suppliers can enormously benefit cost management in acquiring floor gratings. Long-term relationships with reputable suppliers might result in discounts, priority during supply shortages, or access to the newest manufacturing technologies, which can offer both cost effectiveness and state-of-the-art solutions. In conclusion, understanding the price variance in floor grating involves more than just looking at the upfront cost. It demands a comprehensive analysis of material performance, manufacturing intricacies, application environment, and ancillary costs such as transportation and compliance with industry standards. By collaborating closely with industry experts and leveraging long-standing supplier relationships, businesses can navigate these variables effectively, ensuring they secure grating solutions that are both cost-effective and fit for purpose. This holistic approach not only ensures cost savings in the short term but also guarantees sustained performance and safety over the lifespan of the installed gratings.

The cost of transportation and installation should not be overlooked when considering floor grating pricing. Heavy and bulky materials like steel add substantial shipping costs, which may vary depending on the distance from manufacturer to installation site. Installations in challenging environments or remote locations might necessitate specialized equipment or labor, further influencing the overall cost. In addition to these factors, regulatory standards and certifications, such as ISO certifications for quality management and environmental standards, play a pivotal role. Products that comply with higher industry standards often command premium prices due to their guaranteed performance and safety assurances. Establishing trust with suppliers can enormously benefit cost management in acquiring floor gratings. Long-term relationships with reputable suppliers might result in discounts, priority during supply shortages, or access to the newest manufacturing technologies, which can offer both cost effectiveness and state-of-the-art solutions. In conclusion, understanding the price variance in floor grating involves more than just looking at the upfront cost. It demands a comprehensive analysis of material performance, manufacturing intricacies, application environment, and ancillary costs such as transportation and compliance with industry standards. By collaborating closely with industry experts and leveraging long-standing supplier relationships, businesses can navigate these variables effectively, ensuring they secure grating solutions that are both cost-effective and fit for purpose. This holistic approach not only ensures cost savings in the short term but also guarantees sustained performance and safety over the lifespan of the installed gratings.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024