loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

3 月 . 06, 2025 16:23

Back to list

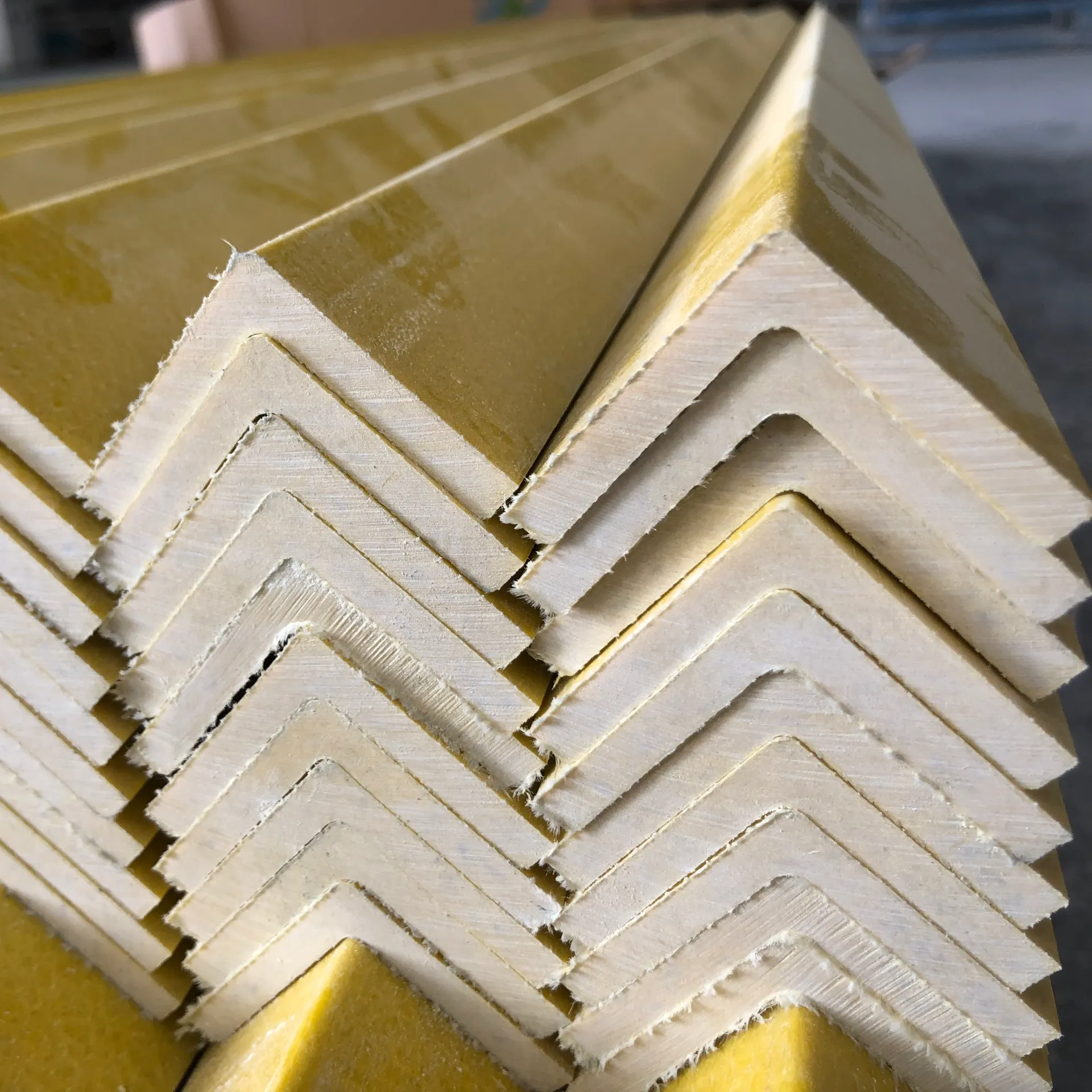

Anti- Corrosion Cost Effective FRP Pultrusion Grating

The process of selecting floor grating is a crucial decision for industries that prioritize safety, durability, and cost-effectiveness. The price of floor grating varies depending on numerous factors including the material, specifications, and market demand. Understanding these variables not only assists in budgeting but also ensures a sound investment that meets specific needs. In this article, we delve into the complexities of floor grating prices, drawing on professional experiences and industry expertise to provide authoritative insights into your purchasing decision.

Navigating through these considerations requires a blend of expertise and strategic decision-making. Consulting with engineers or industry experts who can assess specific project needs and recommend suitable materials and specifications can be invaluable. Their authoritative perspective, grounded in real-world application and industry knowledge, lends credibility to the decision-making process. Trustworthiness in sourcing floor gratings is critical. Brands and suppliers with a long-standing reputation for quality and reliability tend to offer products that not only meet safety standards but also provide investment longevity. Reviews, testimonials, and case studies can provide insights into the performance and durability of a product, enhancing trust among prospective buyers. Safety and compliance with industry standards are paramount. Non-compliance not only poses safety risks but can also lead to legal and financial repercussions. Therefore, understanding and ensuring conformance with relevant standards, such as those set by OSHA or other national bodies, is crucial during the procurement process. In conclusion, the price of floor grating is influenced by material choice, dimensions, market conditions, and long-term costs such as installation and maintenance. Engaging with knowledgeable professionals and reliable suppliers can greatly enhance the decision-making process, ensuring that the selected grating meets both budgetary constraints and safety requirements. By holistically evaluating all these elements, businesses can rightly invest in a solution that proves to be both cost-effective and durable over time, maintaining operational efficiency and safety standards.

Navigating through these considerations requires a blend of expertise and strategic decision-making. Consulting with engineers or industry experts who can assess specific project needs and recommend suitable materials and specifications can be invaluable. Their authoritative perspective, grounded in real-world application and industry knowledge, lends credibility to the decision-making process. Trustworthiness in sourcing floor gratings is critical. Brands and suppliers with a long-standing reputation for quality and reliability tend to offer products that not only meet safety standards but also provide investment longevity. Reviews, testimonials, and case studies can provide insights into the performance and durability of a product, enhancing trust among prospective buyers. Safety and compliance with industry standards are paramount. Non-compliance not only poses safety risks but can also lead to legal and financial repercussions. Therefore, understanding and ensuring conformance with relevant standards, such as those set by OSHA or other national bodies, is crucial during the procurement process. In conclusion, the price of floor grating is influenced by material choice, dimensions, market conditions, and long-term costs such as installation and maintenance. Engaging with knowledgeable professionals and reliable suppliers can greatly enhance the decision-making process, ensuring that the selected grating meets both budgetary constraints and safety requirements. By holistically evaluating all these elements, businesses can rightly invest in a solution that proves to be both cost-effective and durable over time, maintaining operational efficiency and safety standards.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024