loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Affordable Options for Floor Grating Solutions and Pricing Information

When considering the installation of floor grating in both commercial and industrial settings, one of the most crucial factors to evaluate is the pricing. Floor grating serves a myriad of purposes, including safety, drainage, and structural support. Its applications span across a variety of industries, from manufacturing to wastewater treatment facilities. Understanding the price dynamics of floor grating can significantly influence purchasing decisions.

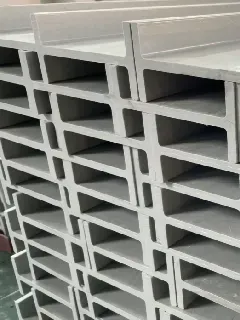

Floor grating is typically made from materials like steel, fiberglass, or aluminum, each contributing differently to cost variations. Steel grating, for instance, offers robust strength and durability, making it suitable for heavy-duty environments. However, it can be more expensive compared to options made from aluminum or fiberglass, especially when considering factors like corrosion resistance coatings. Aluminum grating, while lighter and resistant to rust, may not support as much weight as its steel counterpart, which can be a determining factor in certain applications.

Another important aspect impacting price is the type of grating. Common styles include bar grating, slotted grating, and expanded metal grating. Bar grating tends to be more costly due to its manufacturing process, which requires greater material use and engineering precision. On the other hand, expanded metal grating might serve as a budget-friendly alternative for areas with lower traffic and lighter loads.

Additionally, custom fabrication can contribute significantly to cost. If a project requires specific dimensions or load requirements that deviate from standard sizes, custom grating solutions will generally lead to an increase in pricing. This necessitates a careful evaluation of project needs and the potential for off-the-shelf products to minimize costs.

floor grating price

Bulk purchasing can also play a critical role in the pricing strategy. Many suppliers offer discounts for large orders, which can help reduce the overall expenditure significantly. Therefore, it is often prudent for businesses to assess their long-term needs and strategize accordingly to take advantage of these cost benefits.

Furthermore, installation costs should not be overlooked when considering the total price of floor grating

. Some materials may require specialized installation techniques that could increase labor costs.In conclusion, the price of floor grating is influenced by several factors, including material type, style, custom requirements, and installation. By understanding these elements, purchasers can make informed decisions that balance quality and cost, ultimately benefiting their projects in safety and efficiency.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024