loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

floor metal grating

The Importance of Floor Metal Grating A Comprehensive Overview

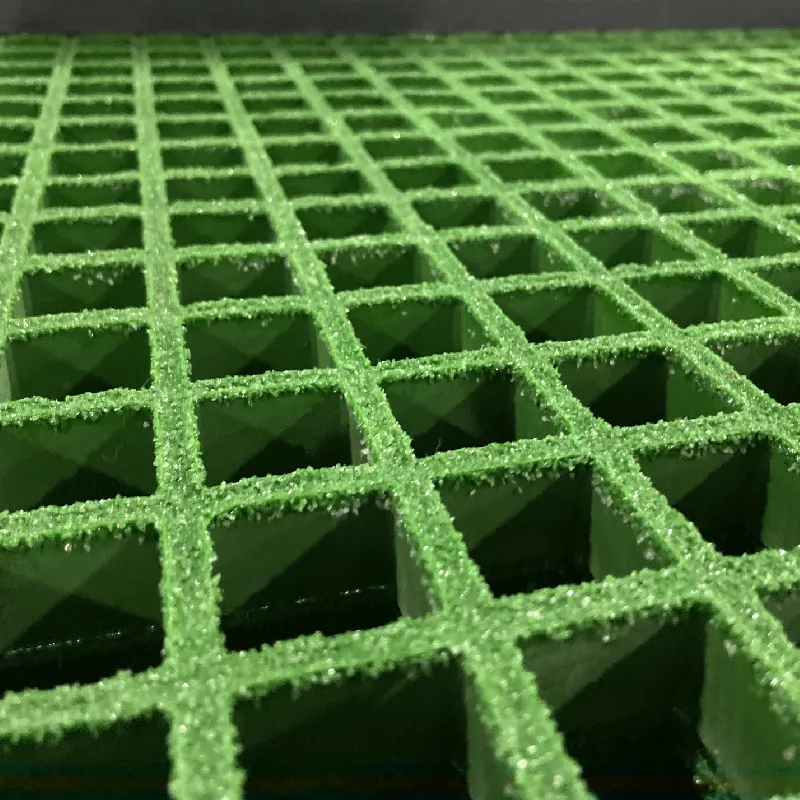

Floor metal grating is an essential component used in various industrial and commercial applications. It serves multiple purposes, including providing a safe walking surface, facilitating drainage, and enhancing ventilation. This article explores the various aspects of floor metal grating, including its types, benefits, applications, and maintenance.

Types of Floor Metal Grating

Floor metal grating comes in various types, the most common being welded grating, pressure-locked grating, and swage-locked grating.

1. Welded Grating - This type consists of crossbars and bearing bars welded together to form a grid-like pattern. It boasts exceptional strength and is suitable for heavy-duty applications.

2. Pressure-Locked Grating - This grating type uses pressure to lock the bearing bars and crossbars together, creating a stable and robust surface. It is often used in environments where a smooth finish is required.

3. Swage-Locked Grating - Swage-locked grating is manufactured by swaging the bearing bars so that they are anchored in the crossbars. This design minimizes the weight without sacrificing strength.

Benefits of Floor Metal Grating

One of the key advantages of floor metal grating is its strength-to-weight ratio. It allows heavy loads to be supported while remaining lightweight enough for easy installation. Moreover, metal grating is durable and resistant to corrosion, making it ideal for outdoor applications or environments with high humidity.

floor metal grating

Another significant benefit is safety. The open design of metal grating allows for water and debris to pass through, reducing the likelihood of slips and falls. This feature is crucial in industrial settings, where spills can lead to hazardous conditions.

Applications of Floor Metal Grating

Floor metal grating is utilized in various sectors, including manufacturing, construction, and commercial buildings. In industrial plants, it is often used for walkways, platforms, and mezzanines, providing workers a safe and durable surface.

In the construction industry, metal grating can serve as flooring in elevators and staircases. Its lightweight nature and flexible design allow it to be easily adapted to diverse architectural needs.

Commercially, floor metal grating finds applications in shopping malls, auditoriums, and airports as it contributes to effective drainage and ventilation, ensuring a clean and safe environment for patrons.

Maintenance of Floor Metal Grating

Proper maintenance is essential for ensuring the longevity of floor metal grating. Regular inspections should be conducted to identify any signs of wear or corrosion. Cleaning should be performed periodically to remove debris and prevent the buildup of hazardous substances. In areas exposed to harsh chemicals or extreme weather conditions, protective coatings may be applied to enhance durability.

In conclusion, floor metal grating is a versatile and valuable material that plays a vital role in maintaining safety and efficiency across various applications. Its strength, durability, and ability to facilitate drainage make it an essential choice for industrial, commercial, and construction projects. By understanding its types, benefits, applications, and maintenance requirements, individuals and organizations can make informed decisions about utilizing metal grating in their facilities.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024