loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp bar

The Role of FRP Bars in Modern Construction

In recent years, the construction industry has witnessed a growing trend toward the use of Fiber Reinforced Polymer (FRP) bars as a vital component in structural applications. These innovative materials are becoming increasingly popular due to their unique properties that offer several advantages over traditional steel reinforcement. This article will explore the characteristics, benefits, and applications of FRP bars in construction.

Understanding FRP Bars

FRP bars are composite materials created by combining high-strength fibers such as glass, carbon, or aramid with a polymer resin. This combination results in a lightweight, corrosion-resistant, and non-conductive material that is ideal for use in various construction applications. The fibrous reinforcement provides exceptional tensile strength, making FRP bars effective for reinforcing concrete structures.

One of the most significant advantages of FRP bars is their resistance to corrosion. Unlike traditional steel, which can rust and deteriorate when exposed to moisture and chemicals, FRP bars maintain their structural integrity in harsh environments. This is particularly beneficial in applications such as bridge construction, marine structures, and chemical processing plants, where exposure to corrosive elements is common.

Advantages of Using FRP Bars

1. Corrosion Resistance As mentioned earlier, the corrosion-resistant properties of FRP bars significantly enhance the lifespan of concrete structures. This results in lower maintenance costs and extended service life, making FRP bars a cost-effective solution over time.

2. Lightweight FRP bars are considerably lighter than steel reinforcement bars (rebars). This lightweight nature reduces the overall weight of construction elements, allowing for easier handling, transportation, and installation. It also minimizes the load on supporting structures, potentially enabling the design of lighter foundations.

3. Non-Magnetic and Non-Conductive FRP materials do not conduct electricity, making them suitable for applications where magnetic interference or electrical conductivity could pose a problem. This feature is particularly advantageous in constructing buildings such as hospitals or data centers, where electronic equipment is sensitive to interference.

frp bar

4. High Strength-to-Weight Ratio FRP bars have an impressive strength-to-weight ratio, ensuring that they can withstand significant loads despite their lightweight nature. This property allows engineers to design more efficient and effective structures, optimizing material usage without compromising safety.

5. Versatility and Design Flexibility FRP bars can be manufactured in various shapes and sizes, allowing for greater flexibility in design. Architects and engineers can utilize FRP bars in unique configurations and applications, expanding the possibilities of modern architectural design.

Applications of FRP Bars

The applications of FRP bars are vast and varied. Some of the notable uses include

- Reinforced Concrete Structures FRP bars are increasingly used to reinforce concrete beams, slabs, and columns, effectively enhancing their structural performance and durability. - Bridge Construction Given their corrosion resistance, FRP bars are ideal for bridges, particularly those exposed to harsh environmental conditions such as saltwater or de-icing chemicals. - Retrofitting and Strengthening Existing structures can be retrofitted with FRP bars to improve load-bearing capacity and extend their lifespan. This application is especially valuable for older or deteriorating structures.

- Precast Concrete Elements FRP bars are commonly used in precast concrete elements, enabling faster and more efficient assembly on-site.

- Marine Structures In marine environments where exposure to saltwater is a concern, FRP bars offer an excellent solution for constructing docks, piers, and other waterfront structures.

Conclusion

The increasing adoption of FRP bars in construction is indicative of the industry's shift towards more sustainable, durable, and efficient materials. With their superior properties, including corrosion resistance, lightweight design, and high tensile strength, FRP bars are poised to play a pivotal role in shaping the future of construction. As the demand for durable and high-performance materials continues to rise, FRP technology is likely to evolve further, ushering in a new era of innovation in the construction sector. This makes it essential for engineers, designers, and construction professionals to stay informed about the latest developments in FRP technology to enhance the quality and longevity of their projects.

-

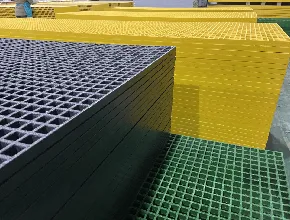

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024