loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Durability and Performance of FRP Bars in Concrete Structures for Enhanced Strength

FRP Bars in Concrete A Revolutionary Approach to Reinforcement Technology

In recent years, the construction industry has witnessed a significant shift towards advanced materials, one of which is Fiber Reinforced Polymer (FRP) bars. These innovative materials, composed of a combination of high-strength fibers and polymer resins, have emerged as a viable alternative to traditional steel reinforcement bars (rebar) in concrete structures. The integration of FRP bars into concrete offers numerous advantages, including enhanced durability, reduced weight, and increased corrosion resistance, making them particularly attractive for a range of applications.

Understanding FRP Bars

FRP bars are composed of fibers such as glass, carbon, or aramid, embedded in a polymer matrix. This structure imparts remarkable strength and stiffness characteristics while maintaining a lightweight profile. The manufacturing process allows for tailoring these materials to specific application needs, offering a versatility that is often unattainable with conventional materials. The dimensional stability, along with superior tensile strength-to-weight ratios of FRP bars, makes them suitable for use in various environments, particularly where high performance is critical.

Advantages Over Traditional Steel Reinforcement

1. Corrosion Resistance One of the most significant benefits of FRP bars is their resistance to corrosion. Unlike steel, which can deteriorate when exposed to moisture and aggressive chemicals, FRP materials are inherently non-corrosive. This characteristic makes them ideal for structures located in marine environments, chemical processing plants, or areas subject to de-icing salts.

2. Lightweight The reduced weight of FRP bars simplifies handling and can lead to lower transportation costs. This lightweight nature can also result in reduced overall dead loads on structures, allowing for more significant design flexibility. In seismic areas, lighter structures can offer better performance during earthquakes.

3. High Strength-to-Weight Ratio FRP bars exhibit higher tensile and shear strengths compared to traditional materials. Their superior strength characteristics enable thinner sections and lighter design elements while maintaining structural integrity. This can result in more cost-effective designs and reduced material usage.

4. Electromagnetic Transparency FRP materials do not interfere with electromagnetic signals, making them suitable for use in applications where maintaining signal integrity is crucial. This property is advantageous in constructing structures where communication equipment is used, such as bridges, tunnels, and transmission towers.

frp bars in concrete

5. Longer Lifecycle Structures that utilize FRP bars tend to have a longer service life due to reduced maintenance needs and their durability against environmental factors. The long-term cost savings associated with this longevity make FRP an economically viable option, despite the higher initial material costs.

Applications of FRP Bars in Concrete

The versatility of FRP bars extends to various applications in the construction sector. They are commonly used in the bridge industry, where their corrosion resistance and lightweight characteristics provide enhanced durability and performance. In addition, FRP bars are gaining traction in precast concrete products, such as slabs, walls, and piles. Their application in retrofitting and strengthening existing structures has also expanded, providing engineers with innovative solutions to enhance the load-carrying capacity of aging infrastructure.

Furthermore, FRP bars offer significant benefits in challenging environments, such as infrastructure projects in coastal regions or areas prone to harsh weather conditions. The benefits of corrosion resistance and superior strength make FRP bars an attractive choice for marine structures, parking garages, and wastewater treatment facilities, among others.

Challenges and Considerations

Despite the numerous advantages, the adoption of FRP bars in concrete construction does pose some challenges. The initial cost remains higher than that of conventional steel reinforcement, which can deter some projects from considering this technology. Additionally, there are still aspects of design codes and standards that require more development to accommodate the unique properties of FRP materials.

Furthermore, the implementation of FRP technology requires knowledge and expertise to ensure proper handling, installation, and design integration. As the industry evolves, increased research and development, along with advances in construction practices, will likely mitigate these challenges, allowing for the broader acceptance of FRP bars in concrete.

Conclusion

The integration of FRP bars into concrete construction represents a significant advancement in reinforcement technology. With their numerous advantages—such as corrosion resistance, reduced weight, and higher strength—FRP bars are poised to play a vital role in shaping the future of the construction industry. As the demand for durability and longevity in infrastructure continues to grow, the utilization of FRP technology offers a promising path forward, ensuring structures can withstand the test of time.

-

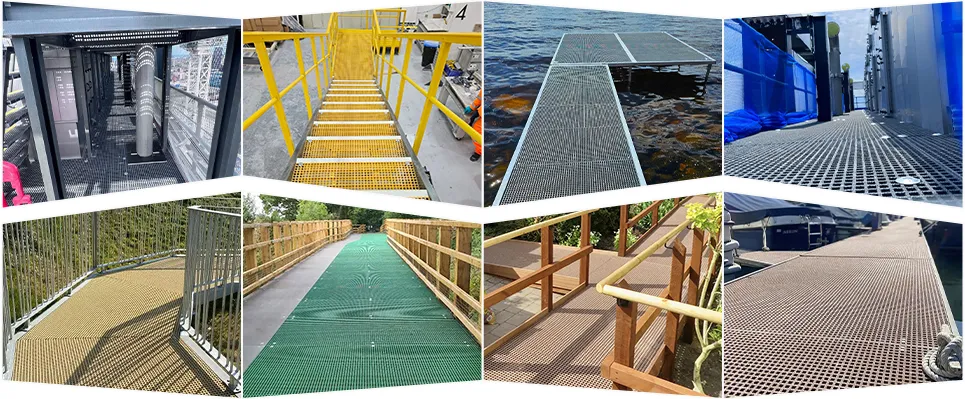

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024