loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 16, 2025 08:47

Back to list

frp vessel for water treatment

Fiberglass Reinforced Plastic (FRP) C channels are increasingly becoming a staple in various industries, offering diverse applications owing to their robust properties. These composite materials are crafted by combining polyester resin with fiberglass, providing a formidable strength-to-weight ratio that surpasses conventional materials like steel and aluminum. The unique structure of FRP C channels makes them indispensable for architects, engineers, and construction professionals seeking reliable, efficient, and sustainable building solutions.

Despite their apparent advantages, the expertise required to work with FRP C channels cannot be underestimated. It is crucial to ensure proper handling and installation by professionals proficient in composite materials to fully capitalize on their attributes. Installation errors can diminish their effectiveness and compromise safety, making the role of skilled technicians and engineers indispensable in utilizing FRP C channels effectively. Investing in workforce training and certification ensures that these materials are applied correctly, providing optimal performance and longevity. An often overlooked but equally important characteristic of FRP C channels is their environmental friendliness. As industries increasingly shift towards sustainable practices, the recyclability and reduced environmental impact of FRP materials contribute significantly to green building initiatives. By opting for FRP C channels, companies reinforce their commitment to environmental responsibility, a factor that can appeal to eco-conscious clients and investors. This can also open up opportunities for enhanced marketing strategies aimed at promoting sustainable business practices. Authoritative bodies and industry experts recognize the myriad benefits of FRP C channels, further solidifying their reputation as a preferred building material. Standards and certifications developed by organizations such as the American Society for Testing and Materials (ASTM) ensure that these materials meet stringent quality and safety guidelines. Adherence to these standards not only affirms the credibility of FRP products but also instills confidence in end-users regarding their application. In conclusion, FRP C channels offer a potent combination of versatility, durability, and sustainability, positioning them as an indispensable component for modern construction and industrial applications. The evolving demands of contemporary architecture and engineering call for innovative materials that align with strict performance and environmental standards, and FRP C channels rise to meet these challenges. Embracing these advanced materials can lead to transformative advancements in structural integrity, safety, and eco-friendliness, making them an invaluable asset for the forward-thinking professional.

Despite their apparent advantages, the expertise required to work with FRP C channels cannot be underestimated. It is crucial to ensure proper handling and installation by professionals proficient in composite materials to fully capitalize on their attributes. Installation errors can diminish their effectiveness and compromise safety, making the role of skilled technicians and engineers indispensable in utilizing FRP C channels effectively. Investing in workforce training and certification ensures that these materials are applied correctly, providing optimal performance and longevity. An often overlooked but equally important characteristic of FRP C channels is their environmental friendliness. As industries increasingly shift towards sustainable practices, the recyclability and reduced environmental impact of FRP materials contribute significantly to green building initiatives. By opting for FRP C channels, companies reinforce their commitment to environmental responsibility, a factor that can appeal to eco-conscious clients and investors. This can also open up opportunities for enhanced marketing strategies aimed at promoting sustainable business practices. Authoritative bodies and industry experts recognize the myriad benefits of FRP C channels, further solidifying their reputation as a preferred building material. Standards and certifications developed by organizations such as the American Society for Testing and Materials (ASTM) ensure that these materials meet stringent quality and safety guidelines. Adherence to these standards not only affirms the credibility of FRP products but also instills confidence in end-users regarding their application. In conclusion, FRP C channels offer a potent combination of versatility, durability, and sustainability, positioning them as an indispensable component for modern construction and industrial applications. The evolving demands of contemporary architecture and engineering call for innovative materials that align with strict performance and environmental standards, and FRP C channels rise to meet these challenges. Embracing these advanced materials can lead to transformative advancements in structural integrity, safety, and eco-friendliness, making them an invaluable asset for the forward-thinking professional.

Share

Latest news

-

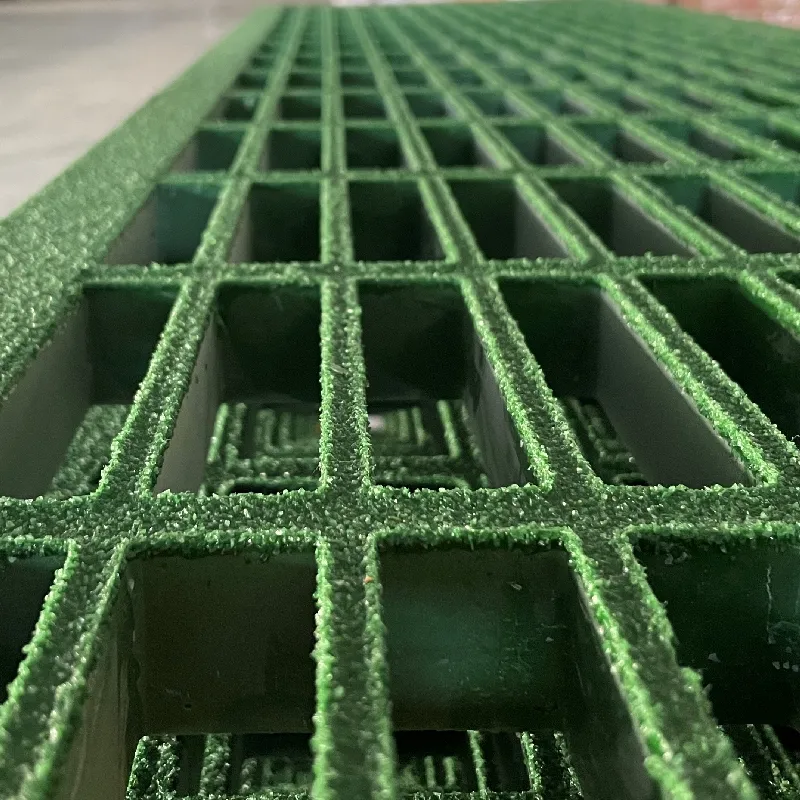

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024