loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Cost of FRP Channel Options in Today's Market

Understanding the Dynamics of FRP Channel Pricing

In the modern construction and manufacturing industries, the use of materials that combine strength, durability, and lightweight properties is essential. One such material that has gained significant importance is Fiber Reinforced Polymer (FRP). Among the various forms of FRP utilized in construction and architecture, the FRP channel stands out due to its versatility and structural integrity. As demand for such materials rises, understanding the pricing dynamics of FRP channels becomes crucial for industry stakeholders, from manufacturers to contractors and end-users.

What is FRP?

Fiber Reinforced Polymer (FRP) is a composite material consisting of a polymer matrix reinforced with fibers that provide strength and rigidity. Common fibers used in FRP production include glass, carbon, and aramid. These materials are highly regarded for their corrosion resistance, lightweight properties, and excellent tensile strength, making them suitable for a variety of applications, including bridges, buildings, and underground infrastructure.

FRP channels specifically are used in structural applications where load-bearing capabilities are essential. They serve as supports, posts, and frames, providing the necessary structural integrity without the added weight of traditional materials like steel or concrete. This makes FRP channels a popular choice in industries seeking to improve efficiency and reduce operational costs.

Factors Influencing FRP Channel Pricing

1. Raw Material Costs The price of raw materials, such as resin and reinforcing fibers, greatly influences the overall cost of FRP channels. Fluctuations in the petroleum industry can lead to changes in resin prices, while the availability and demand for fiber materials also play a significant role.

2. Production Technology Advances in manufacturing technologies can lead to improved efficiencies and lower production costs, which can help stabilize or reduce prices. Conversely, outdated technology may result in higher production costs, impacting pricing strategies.

3. Market Demand As industries increasingly recognize the benefits of using FRP channels, demand has surged. High demand can drive prices up, especially if supply cannot keep pace. Seasonal factors and economic cycles also affect demand, impacting pricing strategies over time.

frp channel price

4. Geographical Variations The cost of FRP channels can vary significantly based on geographic location. Transportation costs, local market conditions, and the presence of manufacturing plants can affect pricing. For instance, buyers in remote areas may face higher prices due to increased shipping costs.

5. Specifications and Customization Customized FRP channels designed to meet specific structural requirements can lead to varied pricing. Detailed specifications regarding dimensions, load-bearing capacities, and resin types can all influence the final price. Off-the-shelf products typically offer more cost-effectiveness compared to custom solutions.

6. Regulatory Factors Compliance with local building codes and regulations can also impact pricing. FRP must meet specific standards, and manufacturers may pass the costs associated with achieving compliance onto consumers.

Pricing Trends and Market Insights

Recent market analyses indicate a steady growth in the FRP channel market. This is attributed to increased investments in infrastructure projects and a growing emphasis on sustainable building practices. As industries transition away from traditional materials due to environmental concerns, the adoption of FRP channels is expected to continue rising.

Despite the many advantages of FRP channels, it is essential for buyers to conduct thorough market research before making purchasing decisions. Comparing prices from multiple suppliers, seeking bulk purchase discounts, and evaluating the total cost of ownership (including installation and maintenance) can help stakeholders make informed choices.

Conclusion

In summary, the pricing of FRP channels reflects a complex interplay of material costs, market demand, and production efficiencies. As the construction and manufacturing industries evolve, understanding these dynamics becomes essential for anyone involved in procurement or supply chain management. By staying informed about market trends and remaining cognizant of the factors influencing pricing, stakeholders can make strategic decisions that align with both budgetary constraints and project requirements.

-

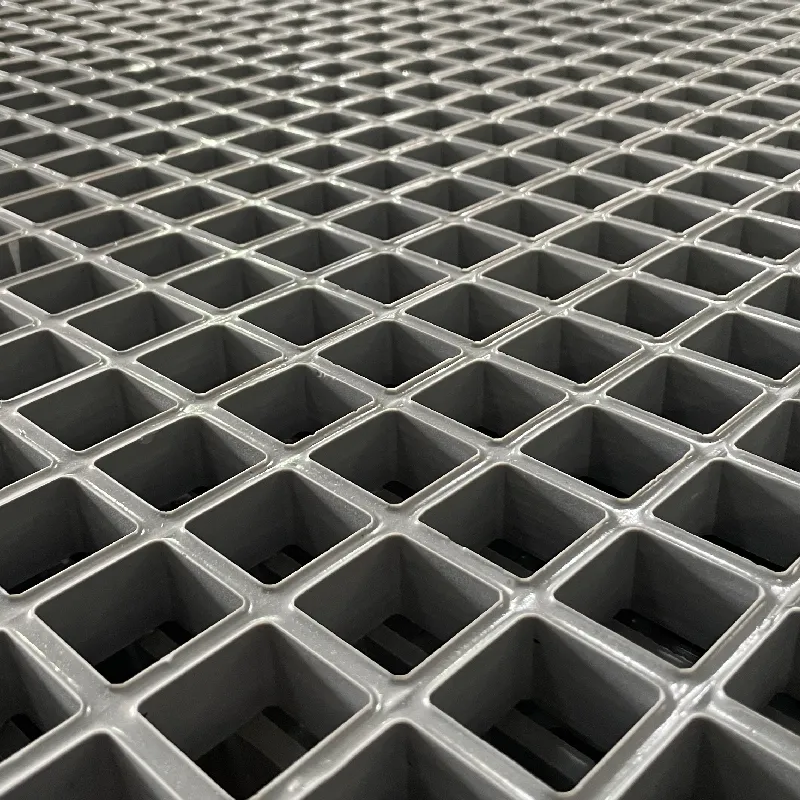

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024