loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Understanding the Function and Application of FRP Discharge Rods in Industry

Understanding FRP Discharge Rods Applications and Benefits

In recent years, the use of fiber-reinforced polymer (FRP) materials has gained considerable attention across various industries, particularly in applications requiring lightweight yet strong components. One significant application of FRP technology is in the manufacture of discharge rods. These rods play an essential role in several sectors, including wastewater management, manufacturing, and construction. This article explores the characteristics, benefits, and typical applications of FRP discharge rods.

What are FRP Discharge Rods?

FRP discharge rods are non-metallic components made from a composite material that combines fibers (usually glass or carbon) with a polymer matrix. This combination results in exceptional mechanical properties, making them significantly lighter than metal rods while maintaining high strength and durability. The manufacturing process of FRP rods generally involves techniques like pultrusion or filament winding, which ensure uniformity and consistency in the product.

Key Characteristics of FRP Discharge Rods

1. Lightweight One of the most significant advantages of FRP discharge rods is their lightweight nature. This feature facilitates easier handling and installation, which can lead to reduced labor costs during operation.

2. Corrosion Resistance FRP materials are inherently resistant to a wide range of chemicals, making them an ideal choice for environments where exposure to corrosive substances is a concern. This quality enhances the lifespan of discharge rods, reducing the need for frequent replacements.

3. High Strength-to-Weight Ratio Despite their lightweight composition, FRP discharge rods exhibit impressive tensile strength. This high strength-to-weight ratio allows them to withstand intense operational stresses without failure.

4. Non-Conductive FRP materials are non-conductive, making FRP discharge rods suitable for use in electrical applications where avoiding electrical hazards is critical.

5. Flexibility in Design The ability to mold FRP into various shapes and sizes allows for customized solutions tailored to specific industrial needs.

frp discharge rod

Applications of FRP Discharge Rods

The unique properties of FRP discharge rods make them suitable for numerous applications

1. Wastewater Treatment In wastewater management, FRP discharge rods are used to transfer effluent and other fluids without the risk of corrosion. Their non-toxic nature also ensures they do not leach harmful substances into the water.

2. Oil and Gas Industry These rods are utilized in offshore and onshore oil drilling operations due to their corrosion resistance, which is essential when dealing with aggressive drilling fluids.

3. Construction and Civil Engineering FRP discharge rods can be employed in constructing retaining walls, drainage systems, and various structural components, offering lightweight solutions without compromising on strength.

4. Marine Applications In marine environments, where materials are often subjected to harsh conditions, FRP discharge rods provide a longer-lasting alternative to traditional materials that may corrode over time.

5. Agricultural Systems In irrigation and drainage systems, FRP discharge rods can be used to help manage water flow effectively while reducing the risk of corrosion commonly seen with metal components.

Conclusion

FRP discharge rods represent a significant advancement in material science and engineering, providing versatile solutions that meet the demands of various industries. Their lightweight, corrosion-resistant, and high-strength characteristics make them an ideal choice for applications where traditional materials may fail. As industries continue to innovate and seek sustainable solutions, the adoption of FRP technologies, including discharge rods, is likely to grow, reinforcing the importance of these materials in modern engineering practices.

-

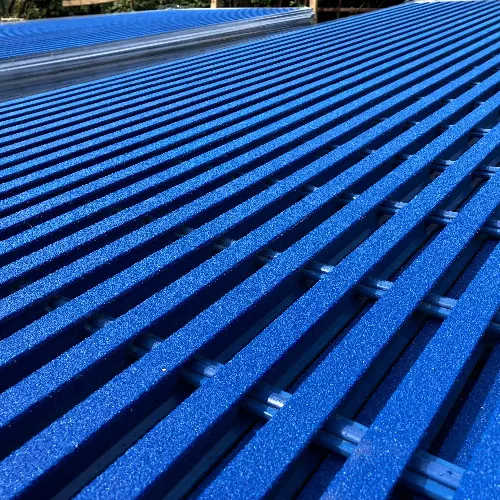

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024