loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp filter vessel

Understanding FRP Filter Vessels Applications and Benefits

FRP (Fiber Reinforced Plastic) filter vessels have emerged as a critical component in various industrial applications, notably in water treatment systems, chemical processing, and environmental protection. These vessels, made of composite materials, offer several advantages over traditional metal or concrete alternatives, making them increasingly popular across diverse sectors.

Understanding FRP Filter Vessels Applications and Benefits

Moreover, FRP filter vessels are lightweight compared to their metal and concrete counterparts. This attribute enables easier transportation and installation. The reduced weight also means that the supporting structures need not be as robust, leading to potential savings in construction materials and costs. Consequently, industries can save on both the initial setup and long-term operational expenses through the installation of FRP filter vessels.

frp filter vessel

Another significant advantage is the flexibility in design. FRP vessels can be molded into various shapes and sizes, tailored to particular applications and space constraints. This flexibility allows engineers to create custom solutions that meet specific filtration needs without compromising on performance. Furthermore, the adaptability of these vessels to different filtration methods—such as sand filters, carbon filters, and multimedia filters—highlights their versatility across diverse applications.

The operational efficiency of FRP filter vessels is worth noting as well. These vessels are designed to optimize flow rates and ensure even distribution of the filtered water, enhancing the overall efficiency of the filtration process. With proper maintenance, they can operate consistently over long periods, ensuring continuous provision of clean water or processed chemicals.

Environmental considerations also play a role in the growing adoption of FRP filter vessels. As industries become more conscious of their environmental impact, the use of materials that are less harmful to ecosystems becomes imperative. FRP can be manufactured to be more environmentally friendly, and many companies are also exploring recycling options for their FRP products once they reach the end of their lifespan.

In conclusion, FRP filter vessels represent a modern solution in the sphere of filtration and processing. With their corrosion resistance, lightweight nature, design flexibility, operational efficiency, and environmentally friendly characteristics, they offer numerous benefits that traditional materials cannot match. As industries continue to seek sustainable and cost-effective solutions, FRP filter vessels are likely to become even more prevalent, driving innovation in water treatment and chemical industries for years to come.

-

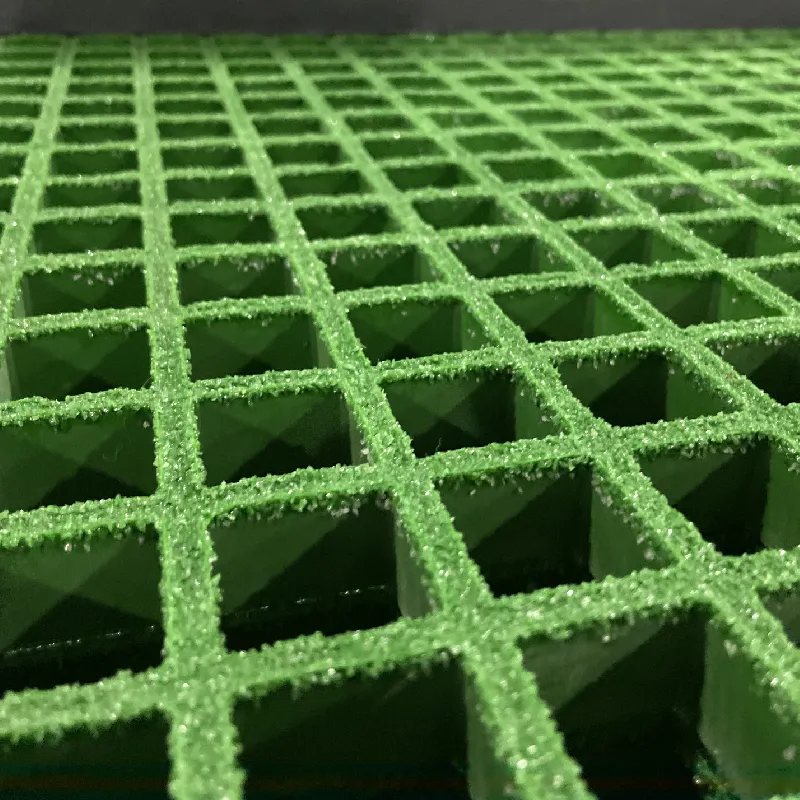

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024