loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Durable and Lightweight FRP Floor Grating for Various Applications and Environments

Understanding FRP Floor Grating A Comprehensive Guide

Fiber Reinforced Plastic (FRP) floor grating has emerged as a favored choice in various industrial and commercial applications due to its unique characteristics and advantages. This innovative material is designed to provide superior strength, durability, and resistance to chemical and environmental factors. In this article, we will delve into the features, benefits, applications, and maintenance of FRP floor grating, giving you a comprehensive overview of its significance in modern construction and infrastructure.

What is FRP Floor Grating?

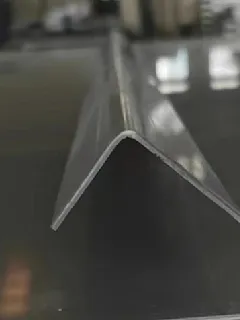

FRP floor grating is made from a composite material that integrates glass fibers within a polymer matrix. This integration allows for a lightweight yet robust construction that can withstand heavy loads and harsh conditions. The manufacturing process involves the use of a thermosetting resin, which is cured to form a solid structure. This grating is available in various sizes, shapes, and load capacities, making it versatile for different applications.

Key Features of FRP Floor Grating

One of the standout features of FRP floor grating is its excellent corrosion resistance. Unlike traditional materials such as steel, which are prone to rusting when exposed to moisture and chemicals, FRP does not corrode, making it ideal for use in environments like chemical processing plants, wastewater treatment facilities, and marine applications. Furthermore, FRP is non-conductive, reducing safety risks associated with electrical hazards.

Another significant advantage is its lightweight nature. FRP floor grating is approximately 75% lighter than steel grating, which simplifies handling and installation. This lightness, combined with high strength, means that structures can bear substantial loads without the need for excessive substructure support, leading to potential cost savings in construction.

Additionally, FRP grating is available in various colors and finishes, allowing for aesthetic customization. It can also be manufactured with anti-slip surfaces, enhancing safety in wet or hazardous environments.

Benefits of Using FRP Floor Grating

The benefits of FRP floor grating are multifaceted. Firstly, its longevity significantly reduces maintenance and replacement costs. FRP does not rot or decay, making it a sustainable choice for long-term projects. Its resistance to UV rays also ensures that it retains its structural integrity and appearance over time.

frp floor grating

Moreover, FRP floor grating is easy to clean. The smooth surface allows for quick removal of debris and contaminants, which is essential in maintaining hygienic environments, particularly in food processing, pharmaceuticals, and sterile facilities.

Environmental sustainability is another crucial factor. The manufacturing process of FRP typically uses less energy than the production of traditional metal materials. Additionally, FRP can be recycled at the end of its lifecycle, reducing waste and promoting a circular economy.

Applications of FRP Floor Grating

FRP floor grating is widely used in various sectors. In industrial environments, it is ideal for walkways, platforms, and stair treads where workers need reliable footing in challenging conditions. The construction industry utilizes FRP for its lightweight characteristics, making it suitable for bridges, loading docks, and rooftop walkways.

Additionally, the marine industry benefits from FRP grating in shipbuilding and dock construction, where resistance to water and salt is crucial. In the chemical sector, the ability to withstand corrosive substances makes FRP an optimal choice for equipment access and maintenance platforms.

Maintenance of FRP Floor Grating

While FRP floor grating is low maintenance, regular inspections are recommended to ensure its longevity and structural integrity. Cleaning is straightforward; most dirt and grime can be removed with a pressure washer or mild detergent. Inspect for any damages or wear, particularly in high-traffic areas, to prevent any potential safety hazards.

Conclusion

In summary, FRP floor grating represents a significant advancement in construction materials, combining strength, durability, and versatility. Its resistance to corrosion, lightweight properties, and low maintenance needs make it an excellent choice for a variety of applications across numerous industries. As businesses increasingly adopt sustainable practices, FRP grating proves to be an environmentally-friendly solution that meets the demands of modern infrastructures. Whether for industrial, commercial, or marine use, FRP floor grating stands as a reliable option for safe and efficient flooring solutions.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024