loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 10, 2025 10:46

Back to list

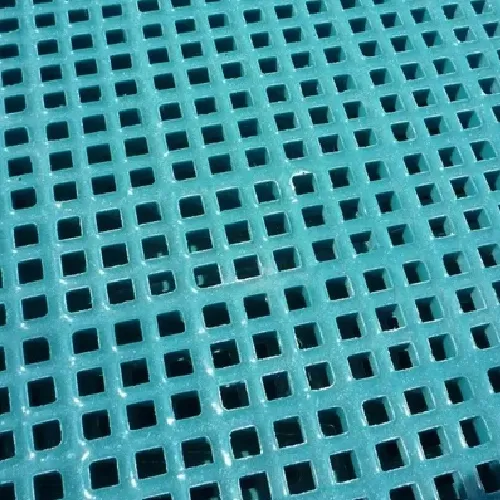

frp grating cost per square foot

Understanding the cost efficiency of fiberglass reinforced plastic (FRP) grating per square foot can significantly influence your buying decision, whether you are an engineer planning an industrial project or a procurement specialist sourcing materials. With its combination of durability, low maintenance needs, and corrosion resistance, FRP grating presents a compelling choice for a range of applications. But how much should you expect to pay per square foot, and what factors contribute to these costs?

Steven Lammers, a structural engineer with over 15 years in industrial design, mentions, The upfront cost for FRP grating might seem steeper, but its service life savings are considerable. In chemical plants where corrosive spillages are frequent, FRP's resilience makes it cost-effective in the long run. FRP Grating in Industry Applications The diversity of FRP grating applications—from oil rigs to public infrastructure—underscores its adaptability and cost-efficiency. For instance, in offshore drilling platforms, the use of FRP grating mitigates the risks of corrosion and slippage, contributing to operational safety while reducing material replacement costs. Environmental engineer Lisa Corrigan remarks, In wastewater treatment facilities, FRP grating outperforms steel due to its non-conductivity and non-corrosive properties, justifying its cost through enhanced safety and longevity. Trustworthiness and Quality Assurance Choosing a reliable supplier is critical to ensuring you obtain high-quality FRP grating. Established manufacturers adhere to stringent quality standards, certifying that their products meet specific industrial requirements. This certification process guarantees the grating brings both structural integrity and compliance with safety standards, which is crucial for maintaining trustworthiness. Stephen Lewis, CEO of a renowned FRP manufacturing company, advises, Always look for FRP gratings compliant with ISO 9001 and ASTM E84 standards to ensure you're investing in quality. The supplier’s reputation in adhering to these protocols often speaks to the longevity and efficacy of their product. In conclusion, understanding the factors influencing FRP grating costs and recognizing its potential long-term value are essential. While initially it may bear a higher cost per square foot compared to alternatives, the enduring benefits—low maintenance, chemical resistance, and environmental durability—make FRP grating a sound investment for various industrial applications. Thus, its cost-effectiveness over time contributes significantly to operational efficiency and resource management.

Steven Lammers, a structural engineer with over 15 years in industrial design, mentions, The upfront cost for FRP grating might seem steeper, but its service life savings are considerable. In chemical plants where corrosive spillages are frequent, FRP's resilience makes it cost-effective in the long run. FRP Grating in Industry Applications The diversity of FRP grating applications—from oil rigs to public infrastructure—underscores its adaptability and cost-efficiency. For instance, in offshore drilling platforms, the use of FRP grating mitigates the risks of corrosion and slippage, contributing to operational safety while reducing material replacement costs. Environmental engineer Lisa Corrigan remarks, In wastewater treatment facilities, FRP grating outperforms steel due to its non-conductivity and non-corrosive properties, justifying its cost through enhanced safety and longevity. Trustworthiness and Quality Assurance Choosing a reliable supplier is critical to ensuring you obtain high-quality FRP grating. Established manufacturers adhere to stringent quality standards, certifying that their products meet specific industrial requirements. This certification process guarantees the grating brings both structural integrity and compliance with safety standards, which is crucial for maintaining trustworthiness. Stephen Lewis, CEO of a renowned FRP manufacturing company, advises, Always look for FRP gratings compliant with ISO 9001 and ASTM E84 standards to ensure you're investing in quality. The supplier’s reputation in adhering to these protocols often speaks to the longevity and efficacy of their product. In conclusion, understanding the factors influencing FRP grating costs and recognizing its potential long-term value are essential. While initially it may bear a higher cost per square foot compared to alternatives, the enduring benefits—low maintenance, chemical resistance, and environmental durability—make FRP grating a sound investment for various industrial applications. Thus, its cost-effectiveness over time contributes significantly to operational efficiency and resource management.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024