loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

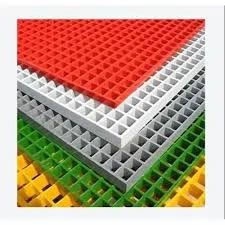

Affordable FRP Grating Options Available for Purchase Online Today

Exploring FRP Grating A Versatile Solution for Various Applications

FRP (Fiber Reinforced Plastic) grating has been gaining momentum across various industries due to its unique properties and benefits. Offering an alternative to traditional materials like steel and wood, FRP grating stands out for its lightweight, durability, and resistance to environmental factors. This article delves into the characteristics of FRP grating and highlights why it is an excellent choice for many applications, including those available for sale.

What is FRP Grating?

FRP grating is composed of a composite material reinforced with fiberglass. The production process involves combining resin with glass fibers, creating a structure that is not only strong but also lightweight. This makes FRP grating easier to handle and install compared to heavier materials. It is available in various configurations, including molded and pultruded options, each serving different application needs.

Benefits of FRP Grating

1. Corrosion Resistance One of the most significant advantages of FRP grating is its exceptional resistance to corrosion. Unlike steel, which can rust over time, FRP is not susceptible to chemicals, moisture, or UV radiation. This makes it an ideal choice for environments prone to harsh chemicals, such as wastewater treatment plants, chemical processing facilities, and marine applications.

2. Lightweight and Strong FRP grating is considerably lighter than metal alternatives, which reduces shipping costs and simplifies installation. Despite its lightweight nature, it maintains impressive strength, making it suitable for heavy loads while ensuring safety.

3. Safety Features The slip-resistant surface of FRP grating enhances safety in workplaces where wet or oily conditions are common. Additionally, its non-conductive properties make it a suitable option for electrical insulation, helping to reduce the risk of electrical hazards.

4. Customization Options FRP grating is available in various sizes, colors, and configurations, allowing for customization to meet specific requirements. This flexibility ensures that users can find suitable grating tailored to their particular space and usage.

frp grating for sale

Applications of FRP Grating

The versatility of FRP grating means it can be used across a wide range of industries, including

- Construction GRP (Glass Reinforced Plastic) grating is used as walkways, stair treads, and platforms in construction sites due to its lightweight nature and strength. - Marine The marine industry benefits from FRP grating’s resistance to water and salt, making it ideal for docks, piers, and boat ramps.

- Industrial In chemical plants and manufacturing facilities, FRP grating provides safe walking surfaces and supports heavy machinery while resisting corrosive substances.

- Environmental Wastewater treatment facilities utilize FRP grating for its longevity and low maintenance requirements, ensuring efficiency in operations.

Purchasing FRP Grating

As demand for FRP grating continues to rise, many manufacturers and suppliers now offer various types of FRP grating for sale. Potential buyers should consider quality, price, and the specific properties necessary for their intended use. It is advisable to work with reputable suppliers who provide comprehensive product information and assurance of the material’s specifications.

Conclusion

In summary, FRP grating represents a modern alternative for various applications due to its durability, lightweight characteristics, and resistance to corrosion and chemicals. As industries strive for efficiency and safety, investing in high-quality FRP grating is a step forward in enhancing operational performance and extending the lifespan of structural elements. Whether you are in construction, marine, or any industrial sector, exploring the available FRP grating options for sale could be a game-changer for your business or project.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024