loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 08, 2025 06:12

Back to list

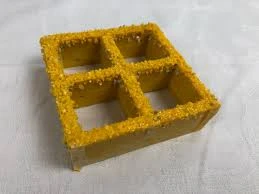

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

FRP (Fiber Reinforced Plastic) grating is revolutionizing industries with its unmatched combination of strength, durability, and lightweight properties. Its innovative design offers a modern solution to several industrial challenges, making it an increasingly sought-after product. This article delves into the compelling reasons why FRP grating should be your material of choice and explores its myriad applications across various sectors.

In the realm of electrical safety, FRP is non-conductive, thus eliminating the risk of electrical hazards. This makes it highly suitable for applications in electrical substations and areas prone to electrical exposure. Its fire-retardant properties also contribute to making it a safer choice than many traditional materials, providing peace of mind in safety-critical applications. Market forecasts suggest that FRP grating demand is poised to grow due to its innovative advantages. Industry experts emphasize that as more companies recognize the life-cycle cost benefits and superior performance attributes of FRP, it will continue to outpace conventional materials. When selecting an FRP grating supplier, it is crucial to consider factors such as product quality, production standards, and customer service. An experienced manufacturer can offer insight-based solutions tailored to specific industrial needs, ensuring that the FRP grating delivers optimal performance over its lifespan. In conclusion, FRP grating stands as a testament to the advancements in material technology, offering unmatched advantages in strength, safety, and sustainability. Its expanding appeal across diverse industries is a testament to its utility and adaptability in solving contemporary industrial challenges. For companies aiming to enhance safety, reduce costs, and embrace innovation, investing in FRP grating presents a strategic choice that promises substantial long-term benefits.

In the realm of electrical safety, FRP is non-conductive, thus eliminating the risk of electrical hazards. This makes it highly suitable for applications in electrical substations and areas prone to electrical exposure. Its fire-retardant properties also contribute to making it a safer choice than many traditional materials, providing peace of mind in safety-critical applications. Market forecasts suggest that FRP grating demand is poised to grow due to its innovative advantages. Industry experts emphasize that as more companies recognize the life-cycle cost benefits and superior performance attributes of FRP, it will continue to outpace conventional materials. When selecting an FRP grating supplier, it is crucial to consider factors such as product quality, production standards, and customer service. An experienced manufacturer can offer insight-based solutions tailored to specific industrial needs, ensuring that the FRP grating delivers optimal performance over its lifespan. In conclusion, FRP grating stands as a testament to the advancements in material technology, offering unmatched advantages in strength, safety, and sustainability. Its expanding appeal across diverse industries is a testament to its utility and adaptability in solving contemporary industrial challenges. For companies aiming to enhance safety, reduce costs, and embrace innovation, investing in FRP grating presents a strategic choice that promises substantial long-term benefits.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024