loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Guide to Installing FRP Grating Efficiently and Effectively for Your Project

Installation of FRP Grating A Comprehensive Guide

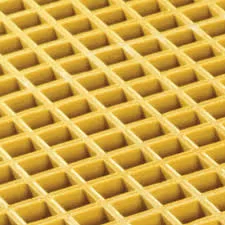

Fiberglass reinforced plastic (FRP) grating has gained popularity in various industries due to its excellent corrosion resistance, high strength-to-weight ratio, and versatility. It is an ideal solution for environments where conventional materials may fail. This article will provide a comprehensive guide on the installation of FRP grating, ensuring that you achieve the best possible results.

Understanding FRP Grating

FRP grating is produced by a process that combines glass fibers with a polymer resin, typically unsaturated polyester or vinyl ester. This results in a non-corrosive, durable product that is lightweight yet strong enough to handle significant loads. It comes in various styles, including molded and pultruded options, with multiple colors and thicknesses available to suit different applications.

Preparing for Installation

1. Planning Before starting the installation process, planning is crucial. Evaluate the specific needs of your project, such as load requirements, environmental considerations, and spatial constraints. Determine the type of FRP grating best suited for your application.

2. Tools and Materials Gather all necessary tools and materials. This typically includes - FRP grating panels - Cutting tools (saw or grinder) - Fasteners (stainless steel hardware is recommended to prevent corrosion) - Adhesive (if required) - Safety equipment (gloves, goggles, etc.)

3. Site Preparation Ensure that the installation site is clean and free from debris. Any uneven surfaces should be rectified to allow for proper placement and support of the grating panels.

Installation Steps

1. Cutting the Panels If you have specific dimensions that differ from standard grating sizes, you may need to cut the panels. It’s essential to use appropriate cutting tools and techniques to achieve a smooth edge. Avoid using excessive force or pressure as this can damage the structure of the FRP.

frp grating installation

2. Setting the Framework Depending on the application, you may need a supporting framework. This could involve installing a beam or frame to which the FRP grating will be attached. The framework should be made of materials that can withstand the same corrosive conditions as the grating.

3. Placing the Grating Position the FRP grating panels on the framework. Ensure that they are aligned correctly and that there are no gaps between them. The panels should be laid out in a manner that distributes the load appropriately.

4. Securing the Panels Utilizing stainless steel screws or clips, secure the grating panels to the framework. It is vital to follow manufacturer recommendations regarding the number and placement of fasteners. Generally, fasteners should be placed at the end and along the edges of each panel to provide maximum stability.

5. Adhesive Application (if necessary) In specific situations where additional support is needed, adhesive can be applied along the edges of the grating before securing it with fasteners. This bond will enhance the stability and durability of the installation.

6. Final Inspection After installation, conduct a thorough inspection to ensure all panels are secure and stable. Pay close attention to areas where multiple panels connect and where fasteners have been applied. It is also a good idea to check for any visible defects or damage.

Maintenance and Care

Although FRP grating requires relatively low maintenance due to its corrosion-resistant properties, routine inspections are advised. Check for any signs of wear and tear, particularly in high-traffic areas. Regular cleaning can help maintain its appearance and functionality, especially in environments with accumulations of debris, grease, or chemicals.

Conclusion

The installation of FRP grating can vastly improve safety and functionality in various settings, from industrial facilities to commercial buildings. By following these guidelines, you can ensure a successful installation process that maximizes the benefits of this innovative material. Whether you are a seasoned professional or a DIY enthusiast, understanding the intricacies of FRP grating installation will lead to safer, more efficient, and corrosion-resistant solutions for your projects.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024