loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Guidelines for Installing FRP Grating Safely and Effectively in Various Applications

Installation of FRP Grating A Comprehensive Guide

Fiberglass Reinforced Plastic (FRP) grating has gained prominence in various industries due to its superior properties, such as lightweight, corrosion resistance, and low maintenance costs. This makes it ideal for environments that are prone to chemical exposure or significant wear and tear. However, proper installation of FRP grating is essential to maximize its benefits and ensure safety and durability. This article provides a detailed overview of the installation process for FRP grating, covering everything from preparation to maintenance.

Preparation for Installation

Before commencing the installation of FRP grating, a careful site assessment is necessary. Evaluate the area where the grating will be installed, noting any potential challenges such as uneven surfaces, access restrictions, or the presence of existing structures. Measurements should be taken accurately to ensure that the grating fits perfectly in the designated space.

Additionally, gather all the required tools and materials before starting the installation process. Essential tools may include a measuring tape, a level, a saw (for any cutting that may be required), a drill, and appropriate fasteners such as screws or anchors specifically designed for FRP applications.

Choosing the Right Grating

Selecting the right FRP grating type is crucial for a successful installation. There are various configurations available, including molded and pultruded grating, each suited for different applications. Consider factors such as load-bearing requirements, environmental conditions, and slip resistance when choosing the grating type. Manufacturers often provide load tables to help in this decision-making process.

Installation Steps

1. Surface Preparation Ensure that the surface where the FRP grating will be installed is clean and free from debris, oil, or any contaminants. Any irregularities should be addressed to provide a level installation surface.

frp grating installation

2. Layout Planning Plan the layout of the grating prior to installation. It is essential to determine the orientation of the grating panels to ensure maximum load distribution. Mark the intended positions on the surface to guide the installation process.

3. Cutting the Grating If necessary, cut the FRP grating to the required dimensions using a suitable saw. Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and a mask to avoid exposure to fiberglass particles during cutting.

4. Placing the Grating Begin laying out the grating sections according to the predetermined layout. Ensure that the panels are aligned correctly and that any required joins or overlaps conform to manufacturer recommendations.

5. Fastening the Grating Secure the grating panels using the appropriate fasteners. Depending on the application, screws may be used to attach the grating to the supporting structure. It is essential to follow the manufacturer's guidelines regarding spacing and type of fasteners to ensure stability.

6. Checking for Stability Once all panels are installed, check for any movement or instability within the grating system. This can be done by walking on the grating to ensure it feels secure and does not flex excessively. Address any issues by tightening fasteners or adding additional support as necessary.

Post-Installation Maintenance

After installation, it is crucial to conduct regular inspections to ensure the integrity of the FRP grating. Check for signs of wear, rust (in metallic components), or damage due to environmental exposure. Cleaning the grating surface is also important, as debris and chemicals can compromise its slip resistance. A mild detergent and water are typically sufficient for cleaning.

Conclusion

The installation of FRP grating involves careful planning, precise execution, and regular maintenance. By following the steps outlined above, individuals and organizations can ensure the grating is installed correctly, maximizing its durability and safety in harsh environments. Whether used in industrial settings, walkways, or platforms, properly installed FRP grating can offer substantial long-term benefits, making it a valuable investment for any project. Always consult with manufacturers and industry professionals to ensure compliance with specific installation guidelines and standards.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

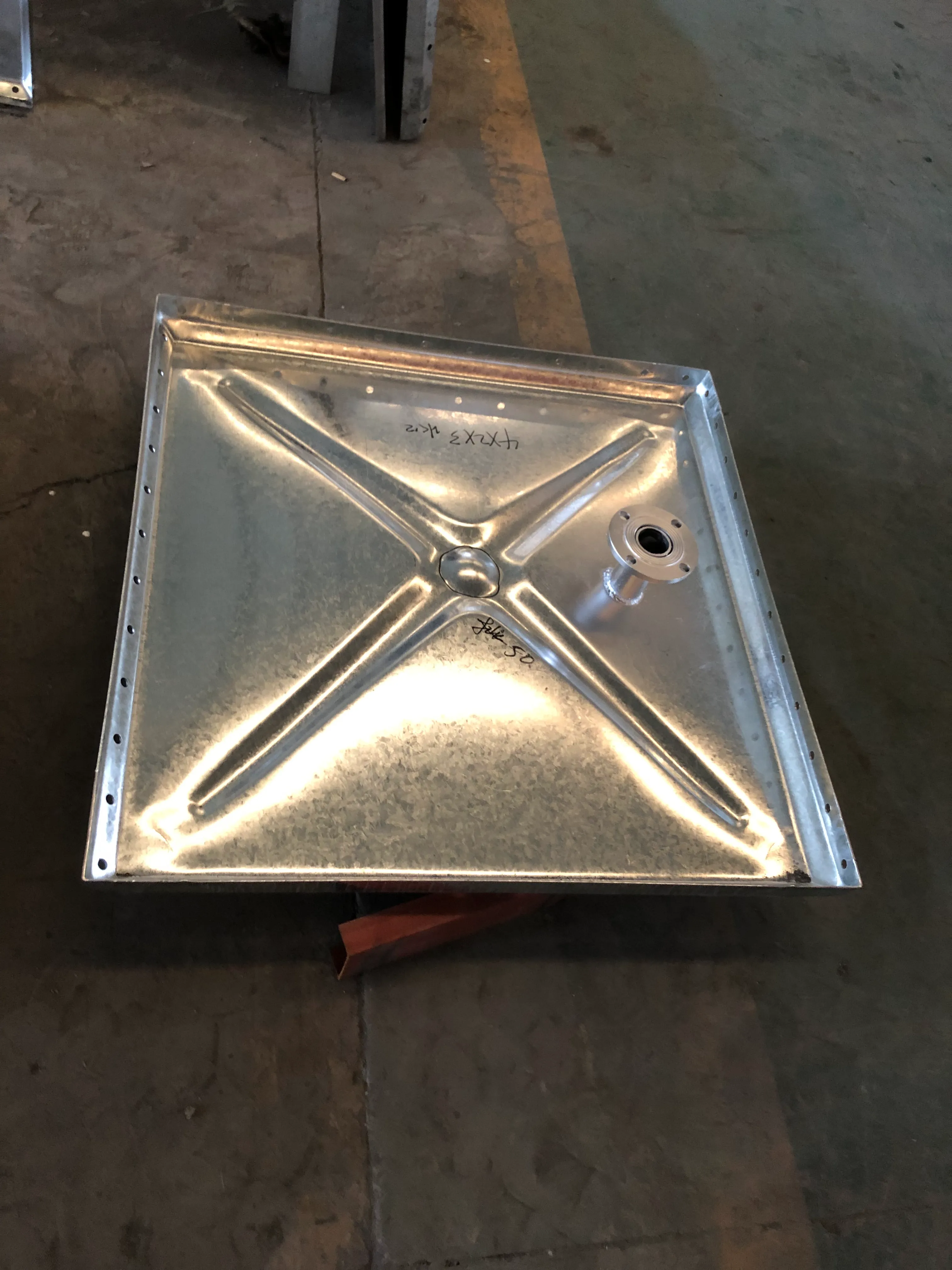

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024