loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

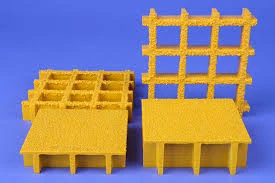

frp grating installation

The Installation of FRP Grating A Comprehensive Guide

FRP (Fiber Reinforced Plastic) grating is a versatile and durable material widely used in various industrial applications, such as chemical plants, waste treatment facilities, and in the construction of pedestrian walkways. The lightweight properties of FRP, combined with its excellent corrosion resistance and non-slip surface, make it an ideal choice for environments exposed to harsh chemicals and weather conditions. However, to maximize its benefits, proper installation is crucial. This article serves as a comprehensive guide to the installation of FRP grating.

Preparation Before Installation

Before starting the installation process, it is essential to gather all necessary tools and materials. Common tools required include

- Safety gear (gloves, goggles, and a dust mask) - Measuring tape - Cutters or saws (appropriate for FRP materials) - Level - Drill - Fasteners (screws, clips, etc.) - Cleaning materials (to ensure the surface is free from dirt, oil, and debris)

Additionally, proper planning is essential. Review the installation area and ensure that the substrate (the underlying surface) is structurally sound and prepared for the grating. Check for any existing installations that may hinder the placement of the new grating.

Measuring and Cutting

Once preparations are complete, measuring and cutting the FRP grating accurately is the next step. Begin by measuring the area where the grating will be installed. Use the measuring tape to determine the length and width required and mark these dimensions clearly on the grating panels.

When it comes to cutting, it is advisable to use a circular saw or a jigsaw fitted with a fine-toothed blade specifically designed for fiberglass materials. Mark the cut lines clearly and wear safety gear, as cutting FRP can produce fine dust particles.

Installation Process

frp grating installation

1. Substrate Preparation Ensure that the substrate is clean, level, and free from any obstructions. Any sharp edges or protrusions should be smoothed out to prevent damage to the grating.

2. Placement of Grating Panels Begin placing the grating panels in the designated area. It's essential to start from one end and work your way to the other, ensuring that each panel fits snugly together. FRP grating systems typically have interlocking designs that allow for easy placement.

3. Fastening the Grating Depending on the specific requirements of your installation, you may need to fasten the grating panels to the substrate. Use appropriate fasteners such as screws, clips, or brackets designed for FRP materials. Ensure that fasteners are evenly spaced according to the manufacturer's recommendations to maintain structural integrity.

4. Leveling Use a level to check that the grating is correctly positioned and even. Any unevenness can lead to safety hazards and potential damage over time.

5. Finishing Touches After installation, inspect the entire grating surface for any gaps or loose panels. Make any necessary adjustments and ensure all fasteners are tightened securely.

Safety Considerations

Safety should always be a priority during the installation of FRP grating. Ensure that workers are wearing appropriate personal protective equipment (PPE) throughout the process. Additionally, keep the installation area clear of hazards and ensure that all tools are used correctly.

Conclusion

The installation of FRP grating is a straightforward process that, when done correctly, offers lasting benefits in terms of durability and safety. Following the steps outlined above will help ensure that your installation is successful. By taking the time to prepare, measure accurately, and follow safety protocols, you will create a robust and reliable grating system. Whether in industrial settings or for pedestrian walkways, properly installed FRP grating can enhance safety and efficiency for years to come.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024