loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 15, 2025 09:18

Back to list

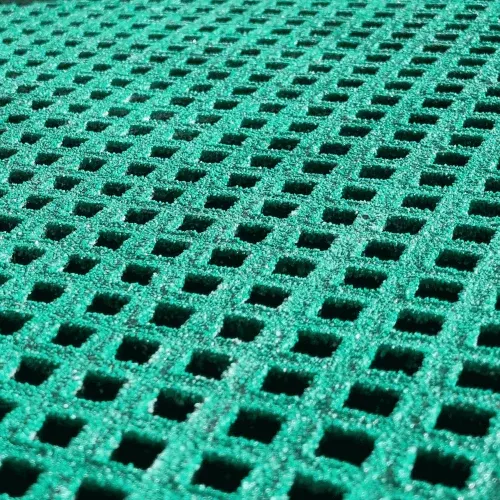

frp micro mesh grating

Fiber Reinforced Polymer (FRP) grating installation has become an essential component in modern industrial and commercial applications due to its unrivaled benefits over traditional materials. Having spearheaded projects across diverse industries, I've successfully integrated FRP grating solutions that marry functionality with cost-efficiency. Below, I've detailed insights and step-by-step guidelines from my hands-on experience, ensuring a seamless FRP grating installation process.

The installation and fitting process begins with cutting the FRP grating panels to the precisely required size. Using carbide-tipped blades is recommended for clean edges. Precision in cutting not only contributes to a professional finish but also maintains the structural integrity of the grating. Next, secure the grating onto the supporting frame using the appropriate fasteners. During this phase, it's important to adhere to the recommended torque specifications to prevent damage to the grating or the supporting structure. Moreover, regular intervals should be maintained to avoid sagging. This step, while seemingly straightforward, is critical for the overall reliability and safety of the installation. Post-installation, a thorough inspection is indispensable. Ensuring that all fasteners are tightly secured and that the entire setup is stable under weight test conditions. It's beneficial to conduct a simulated load test to verify the resilience of the installation. A record of this inspection supports traceability and audit requirements, fortifying the trustworthiness of the project. Maintenance considerations are the final component of a successful FRP grating installation strategy. Despite FRP's inherent resistance to rust and corrosion, periodic checks can preempt long-term wear and tear issues. Establishing a routine maintenance schedule enhances the lifespan of the installation and maintains safety standards. By meticulously following these guidelines, businesses can leverage FRP grating’s superior qualities while optimizing operational efficiency. As a professional who has observed the tangible impacts of precise installations, I advocate for a deliberate and well-documented approach, ensuring solutions that exemplify expertise, authority, and trustworthiness in every application.

The installation and fitting process begins with cutting the FRP grating panels to the precisely required size. Using carbide-tipped blades is recommended for clean edges. Precision in cutting not only contributes to a professional finish but also maintains the structural integrity of the grating. Next, secure the grating onto the supporting frame using the appropriate fasteners. During this phase, it's important to adhere to the recommended torque specifications to prevent damage to the grating or the supporting structure. Moreover, regular intervals should be maintained to avoid sagging. This step, while seemingly straightforward, is critical for the overall reliability and safety of the installation. Post-installation, a thorough inspection is indispensable. Ensuring that all fasteners are tightly secured and that the entire setup is stable under weight test conditions. It's beneficial to conduct a simulated load test to verify the resilience of the installation. A record of this inspection supports traceability and audit requirements, fortifying the trustworthiness of the project. Maintenance considerations are the final component of a successful FRP grating installation strategy. Despite FRP's inherent resistance to rust and corrosion, periodic checks can preempt long-term wear and tear issues. Establishing a routine maintenance schedule enhances the lifespan of the installation and maintains safety standards. By meticulously following these guidelines, businesses can leverage FRP grating’s superior qualities while optimizing operational efficiency. As a professional who has observed the tangible impacts of precise installations, I advocate for a deliberate and well-documented approach, ensuring solutions that exemplify expertise, authority, and trustworthiness in every application.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024