loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Benefits of Fiber Reinforced Plastic Grating Panels in Modern Construction

The Rise of FRP Grating Panels A Modern Solution for Industrial Applications

In today's industrial landscape, the quest for durable, lightweight, and versatile materials is ever-increasing. One of the frontrunners in meeting these demands is Fiber Reinforced Polymer (FRP) grating panels. These advanced materials have found a significant place in various applications, ranging from oil and gas industries to commercial buildings, thanks to their remarkable properties.

Understanding FRP Grating Panels

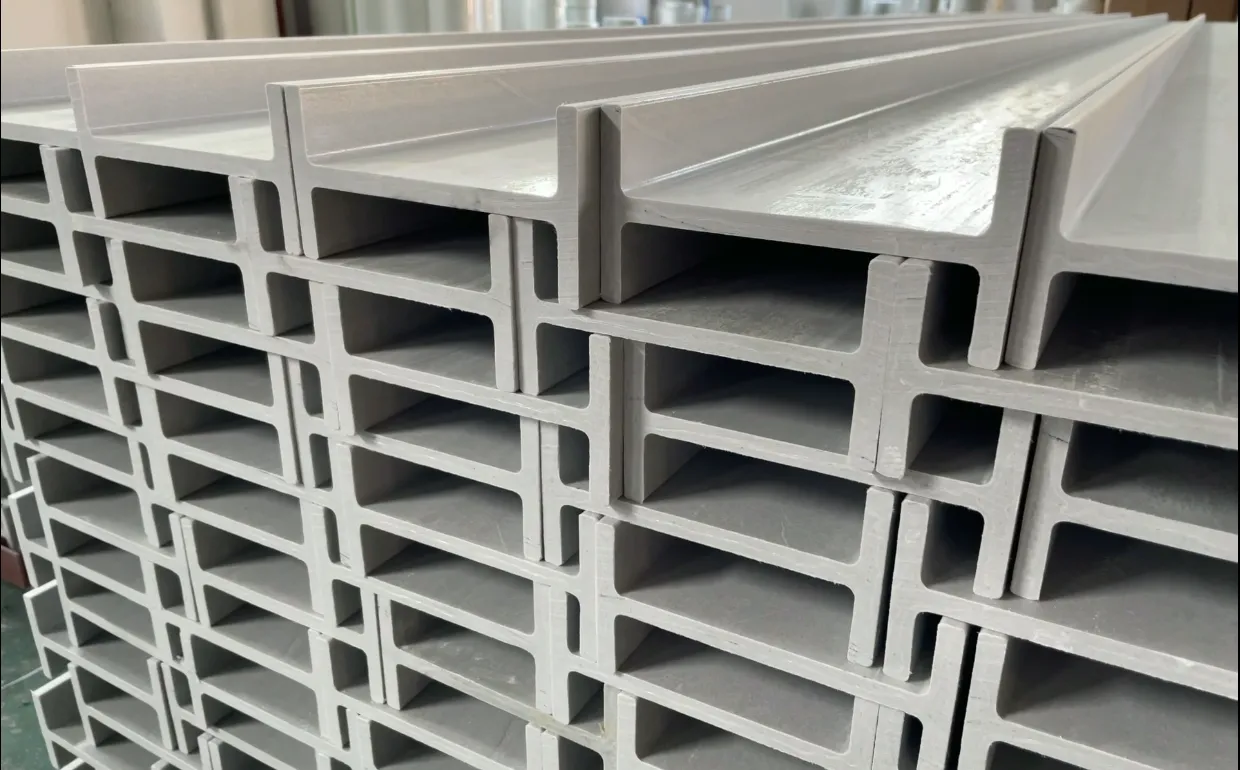

FRP grating panels are made by combining fibers, typically glass or carbon, with a polymer matrix. This unique composition results in a product that is not only strong but also lightweight compared to traditional materials such as steel or wood. The manufacturing process of FRP panels involves a variety of techniques including pultrusion and hand layup, ensuring a consistent quality and performance throughout the product.

Key Advantages of FRP Grating Panels

1. Corrosion Resistance One of the standout features of FRP grating panels is their exceptional resistance to corrosive environments. Unlike metals that can rust or deteriorate when exposed to harsh chemicals, FRP panels maintain their structural integrity, making them ideal for industries such as chemical processing, wastewater treatment, and coastal applications.

2. Lightweight Nature With a significantly lower weight than traditional materials, FRP panels contribute to reduced transport costs and easier installation. This characteristic is particularly beneficial in applications where weight constraints are critical, such as mezzanines and platforms.

3. Safety Features FRP grating panels are designed with safety in mind. They can provide slip-resistant surfaces, which are crucial in environments where there is a risk of spills or wet conditions. Moreover, these panels have a high open area that allows for drainage, further enhancing workplace safety.

frp grating panels

4. Low Maintenance Maintaining FRP grating panels is relatively effortless, as they do not require regular painting or sealing. Their resistance to environmental factors translates into lower lifecycle costs, a major consideration for long-term projects.

5. Versatile Applications The versatility of FRP grating panels allows for their use in various settings, including walkways, platforms, stairways, and even in architectural designs. Their adaptability to custom shapes and sizes makes them suitable for unique or complex projects.

Environmental Impact

In an era where sustainability is paramount, FRP panels also present environmental advantages. They can be manufactured with recyclable materials, and their longevity reduces the environmental impact associated with frequent replacements of conventional materials. Furthermore, their energy-efficient production process contributes to a lower carbon footprint.

Conclusion

As industries continue to evolve, the demand for innovative materials that offer durability, safety, and sustainability remains a top priority. FRP grating panels represent a sophisticated solution to these challenges. Their corrosion resistance, lightweight design, and low maintenance requirements make them an attractive choice for a wide range of applications.

The integration of FRP technology is not just a trend; it is a forward-thinking approach that aligns with modern industrial needs. As awareness of the benefits associated with FRP grating panels grows, it is likely that their usage will expand, paving the way for more efficient and sustainable practices across various sectors. Embracing this material could very well define the future of industrial construction and architectural design, establishing a benchmark for quality and performance.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024