loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 10, 2025 09:12

Back to list

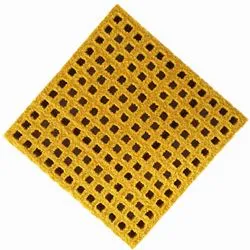

frp grating panels

FRP grating panels have increasingly become a cornerstone material for various industrial and commercial applications, owing to their robust, lightweight, and corrosion-resistant characteristics. As an industry expert with a wealth of experience in composite materials, I've seen firsthand how FRP grating panels can transform infrastructure projects, enhancing both safety and efficiency.

The customization options available with FRP grating panels also contribute to their widespread adoption. Manufacturers can tailor these panels to specific project requirements, offering various panel sizes, thicknesses, and grit surfaces to enhance traction. This level of customization ensures that FRP gratings can effectively address unique challenges, such as providing optimal slip resistance in wet conditions or accommodating specific load-bearing needs. In terms of environmental impact, FRP grating panels are a sustainable choice. During my engagements with projects focusing on sustainability, I've noted that FRP panels are recyclable and require less energy to produce compared to metal grates. This eco-friendly aspect, combined with their prolonged lifespan, makes them a responsible option for environmentally-conscious industries. For decision-makers seeking to optimize both the functionality and safety of their facilities, understanding the benefits of FRP grating panels is essential. By transitioning to FRP, companies not only benefit from superior performance and durability but also demonstrate a commitment to innovation and sustainability in their operations. To conclude, the integration of FRP grating panels within industrial applications is more than just a trend—it's a strategic move towards enhancing operational efficiency and safety. By relying on expert insights and proven applications, businesses can trust that FRP grating panels will continue to deliver exceptional results, reaffirming their status as a leading material choice for modern infrastructure solutions.

The customization options available with FRP grating panels also contribute to their widespread adoption. Manufacturers can tailor these panels to specific project requirements, offering various panel sizes, thicknesses, and grit surfaces to enhance traction. This level of customization ensures that FRP gratings can effectively address unique challenges, such as providing optimal slip resistance in wet conditions or accommodating specific load-bearing needs. In terms of environmental impact, FRP grating panels are a sustainable choice. During my engagements with projects focusing on sustainability, I've noted that FRP panels are recyclable and require less energy to produce compared to metal grates. This eco-friendly aspect, combined with their prolonged lifespan, makes them a responsible option for environmentally-conscious industries. For decision-makers seeking to optimize both the functionality and safety of their facilities, understanding the benefits of FRP grating panels is essential. By transitioning to FRP, companies not only benefit from superior performance and durability but also demonstrate a commitment to innovation and sustainability in their operations. To conclude, the integration of FRP grating panels within industrial applications is more than just a trend—it's a strategic move towards enhancing operational efficiency and safety. By relying on expert insights and proven applications, businesses can trust that FRP grating panels will continue to deliver exceptional results, reaffirming their status as a leading material choice for modern infrastructure solutions.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

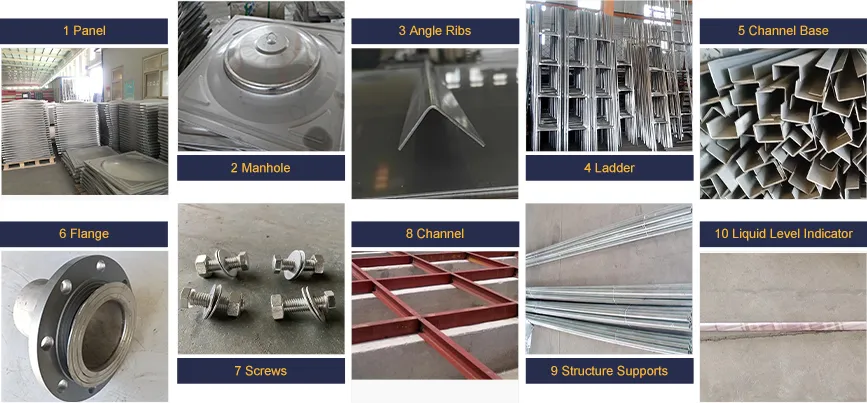

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024