loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 19, 2025 00:33

Back to list

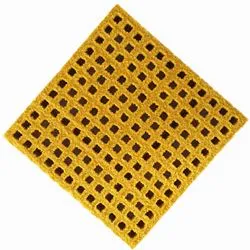

frp grating panels

FRP grating panels, known for their strength, durability, and versatility, have become essential components in a variety of industries. These panels, composed of fiber-reinforced plastic, combine a resilience to environmental factors with a lightweight structure, making them a preferred choice in challenging environments. Backed by decades of engineering advances, FRP grating panels are engineered to meet the demanding needs of industrial floors, walkways, and platforms.

FRP grating panels also contribute significantly to sustainability efforts in construction and manufacturing. Their long lifespan reduces the need for frequent replacements, which not only saves costs but also minimizes waste. Additionally, many manufacturers are now producing FRP grating with environmentally friendly resins, thus further reducing the environmental footprint of these materials. This consideration for sustainability aligns with the growing global emphasis on eco-friendly practices, making FRP grating a forward-thinking choice. The versatility of FRP grating panels cannot be overstated. They are available in diverse resin formulations, thicknesses, and mesh patterns to suit specific applications. For instance, while a high chemical resistance formulation might be essential in a chemical processing plant, a UV-resistant version could be more appropriate for outdoor platforms subjected to direct sunlight. This customization ensures that the panel's performance is optimized for its intended use, offering unmatched specificity compared to traditional materials. In conclusion, FRP grating panels represent a synthesis of advanced material science and practical application. Their capability to withstand harsh conditions while maintaining structural integrity makes them an invaluable asset across several industries. Businesses integrating these panels into their infrastructure not only enhance operational efficacy but also demonstrate a commitment to safety, sustainability, and innovation. As industries continue to evolve, FRP grating panels are poised to remain at the forefront, showcasing the harmonious blend of engineering excellence and environmental responsibility.

FRP grating panels also contribute significantly to sustainability efforts in construction and manufacturing. Their long lifespan reduces the need for frequent replacements, which not only saves costs but also minimizes waste. Additionally, many manufacturers are now producing FRP grating with environmentally friendly resins, thus further reducing the environmental footprint of these materials. This consideration for sustainability aligns with the growing global emphasis on eco-friendly practices, making FRP grating a forward-thinking choice. The versatility of FRP grating panels cannot be overstated. They are available in diverse resin formulations, thicknesses, and mesh patterns to suit specific applications. For instance, while a high chemical resistance formulation might be essential in a chemical processing plant, a UV-resistant version could be more appropriate for outdoor platforms subjected to direct sunlight. This customization ensures that the panel's performance is optimized for its intended use, offering unmatched specificity compared to traditional materials. In conclusion, FRP grating panels represent a synthesis of advanced material science and practical application. Their capability to withstand harsh conditions while maintaining structural integrity makes them an invaluable asset across several industries. Businesses integrating these panels into their infrastructure not only enhance operational efficacy but also demonstrate a commitment to safety, sustainability, and innovation. As industries continue to evolve, FRP grating panels are poised to remain at the forefront, showcasing the harmonious blend of engineering excellence and environmental responsibility.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024