loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 15, 2025 09:11

Back to list

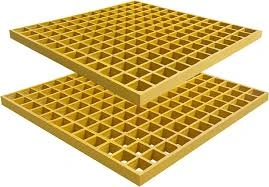

frp grating platform

Fiberglass reinforced plastic (FRP) grating platforms have emerged as an innovative solution in environments demanding safety, durability, and maintenance-free performance. Crafted from a composite material comprising fiberglass and resin, these platforms address multiple challenges prevalent in industries such as marine, chemical processing, and wastewater treatment.

From a maintenance perspective, FRP grating platforms require little to no upkeep. They do not rust, warp, or require recoating, drastically lowering maintenance costs over their lifespan. This characteristic is particularly valued in remote or difficult-to-access installations, where regular maintenance can be challenging and expensive. FRP grating platforms are also environmentally friendly. The production process emits fewer greenhouse gases compared to steel, and the materials can often be recycled, contributing to lower environmental impact. Such benefits can be pivotal for companies focused on sustainability and reducing their environmental footprint. Beyond their physical and operational advantages, opting for FRP grating platforms can influence the bottom line positively. The reduced need for frequent replacements and maintenance translates into cost savings, providing a strong return on investment. A well-chosen FRP grating system can match the fit and function required by industry-specific applications, ensuring longevity and value. This combination of resilience, safety, efficiency, and sustainability underlines FRP grating platforms as a remarkable alternative to conventional materials. Their strategic use across industries underscores not only their versatility and reliability but also their potential to transform operational efficiencies. For decision-makers considering the adoption of superior materials that uphold industry standards and drive cost-effectiveness, FRP grating platforms stand out as a definitive choice. In an era where advanced materials are crucial for maintaining competitive edges, the contribution of FRP solutions cannot be underestimated. Their adoption reflects a commitment to leveraging technology for better, safer, and more sustainable industrial practices.

From a maintenance perspective, FRP grating platforms require little to no upkeep. They do not rust, warp, or require recoating, drastically lowering maintenance costs over their lifespan. This characteristic is particularly valued in remote or difficult-to-access installations, where regular maintenance can be challenging and expensive. FRP grating platforms are also environmentally friendly. The production process emits fewer greenhouse gases compared to steel, and the materials can often be recycled, contributing to lower environmental impact. Such benefits can be pivotal for companies focused on sustainability and reducing their environmental footprint. Beyond their physical and operational advantages, opting for FRP grating platforms can influence the bottom line positively. The reduced need for frequent replacements and maintenance translates into cost savings, providing a strong return on investment. A well-chosen FRP grating system can match the fit and function required by industry-specific applications, ensuring longevity and value. This combination of resilience, safety, efficiency, and sustainability underlines FRP grating platforms as a remarkable alternative to conventional materials. Their strategic use across industries underscores not only their versatility and reliability but also their potential to transform operational efficiencies. For decision-makers considering the adoption of superior materials that uphold industry standards and drive cost-effectiveness, FRP grating platforms stand out as a definitive choice. In an era where advanced materials are crucial for maintaining competitive edges, the contribution of FRP solutions cannot be underestimated. Their adoption reflects a commitment to leveraging technology for better, safer, and more sustainable industrial practices.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024