loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 15, 2025 09:15

Back to list

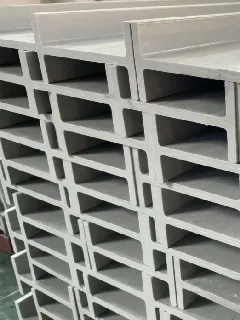

frp grating price

FRP grating has emerged as a leading choice in modern construction and industrial applications due to its versatility, durability, and cost-effectiveness. As industries evolve, understanding the factors influencing FRP grating prices is essential for budgeting and planning projects efficiently.

The supply chain and market trends also influence FRP grating prices. Global supply chain factors, including transportation costs, tariffs, and trade policies, can affect pricing considerably. In addition, fluctuations in demand and the availability of raw materials often lead to price changes. Staying informed about market dynamics helps in timing purchases strategically to achieve cost savings. In terms of application, industries such as oil and gas, wastewater treatment, and construction are experiencing increased demand for FRP grating due to its corrosion resistance and strength-to-weight ratio. Projects within these sectors often demand customized grating solutions, which can affect the pricing structure. Another significant consideration is long-term value. While initial costs might seem higher compared to traditional materials, FRP grating's low maintenance requirements and longevity offer substantial savings over time. Its inherent resistance to rot, rust, and deterioration ensures that replacement costs are minimized, allowing for financial efficiency in long-term projects. When choosing FRP grating products, it's crucial to partner with reputable manufacturers or suppliers who provide transparent pricing and detailed product information. Trusted suppliers can offer valuable insights into the best material and design choices for your specific application, ensuring that the investment is both cost-effective and practical. In conclusion, the pricing of FRP grating is influenced by multiple facets ranging from material quality and manufacturing processes to customization and market conditions. For those in the industry, understanding these factors allows for more informed decisions, ensuring that each purchase aligns with budgetary constraints while meeting superior performance standards. As the market evolves, staying informed and choosing wisely becomes a key element in leveraging FRP grating's full potential and securing a return on investment.

The supply chain and market trends also influence FRP grating prices. Global supply chain factors, including transportation costs, tariffs, and trade policies, can affect pricing considerably. In addition, fluctuations in demand and the availability of raw materials often lead to price changes. Staying informed about market dynamics helps in timing purchases strategically to achieve cost savings. In terms of application, industries such as oil and gas, wastewater treatment, and construction are experiencing increased demand for FRP grating due to its corrosion resistance and strength-to-weight ratio. Projects within these sectors often demand customized grating solutions, which can affect the pricing structure. Another significant consideration is long-term value. While initial costs might seem higher compared to traditional materials, FRP grating's low maintenance requirements and longevity offer substantial savings over time. Its inherent resistance to rot, rust, and deterioration ensures that replacement costs are minimized, allowing for financial efficiency in long-term projects. When choosing FRP grating products, it's crucial to partner with reputable manufacturers or suppliers who provide transparent pricing and detailed product information. Trusted suppliers can offer valuable insights into the best material and design choices for your specific application, ensuring that the investment is both cost-effective and practical. In conclusion, the pricing of FRP grating is influenced by multiple facets ranging from material quality and manufacturing processes to customization and market conditions. For those in the industry, understanding these factors allows for more informed decisions, ensuring that each purchase aligns with budgetary constraints while meeting superior performance standards. As the market evolves, staying informed and choosing wisely becomes a key element in leveraging FRP grating's full potential and securing a return on investment.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024