loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp mesh grating

Exploring the Benefits of FRP Mesh Grating

In recent years, the demand for durable and lightweight materials in construction and engineering has significantly increased. Among these materials, Fiber Reinforced Polymer (FRP) mesh grating has emerged as a versatile solution, widely recognized for its unique properties and applications across various industries. This article delves into what FRP mesh grating is, its advantages, and some of its most common uses.

What is FRP Mesh Grating?

FRP mesh grating is a composite material made from a polymer resin reinforced with glass or carbon fibers. The resulting grids are lightweight, corrosion-resistant, and can be easily manufactured into various shapes and sizes. The mesh structure provides excellent load-bearing capacity while maintaining a high strength-to-weight ratio. This combination makes FRP mesh grating an ideal choice for applications in harsh environments where traditional materials might fail.

Advantages of FRP Mesh Grating

1. Corrosion Resistance One of the most significant benefits of FRP mesh grating is its resistance to corrosion. Traditional metal grating can rust and degrade over time when exposed to moisture, chemicals, and other corrosive elements. In contrast, FRP materials do not corrode, making them suitable for industries such as wastewater treatment, chemical processing, and marine applications.

2. Lightweight The lightweight nature of FRP mesh grating simplifies transportation and installation. This attribute not only reduces labor costs but also minimizes the load on structural supports, making it advantageous in applications where weight is a crucial factor.

3. Durability FRP grating is designed to withstand harsh environmental conditions, including high temperatures, UV exposure, and heavy impacts. This durability leads to lower maintenance costs and a longer lifespan compared to traditional materials.

4. Versatility Available in various sizes, colors, and configurations, FRP mesh grating can be customized to meet specific project requirements. Whether used for flooring, walkways, or platforms, this material can adapt to different design needs.

frp mesh grating

5. Safety FRP mesh grating typically features a slip-resistant surface, enhancing safety in environments where wet or slippery conditions are common. This characteristic is particularly beneficial in industrial settings, construction sites, and public spaces.

Applications of FRP Mesh Grating

FRP mesh grating finds applications in multiple sectors, making it a valuable resource for engineers and construction professionals. Here are some of its most common uses

1. Industrial Flooring In factories, chemical plants, and warehouses, FRP grating provides a safe and sturdy flooring solution. Its slip-resistant surface aids in preventing workplace accidents, while its resistance to chemicals ensures longevity.

2. Access Platforms and Walkways FRP mesh grating is often used to construct access platforms and walkways in hazardous environments, such as oil rigs, waste treatment facilities, and cooling towers. Its lightweight properties facilitate easy installation and maintenance while ensuring worker safety.

3. Bridges and Pedestrian Walkways In civil engineering, FRP grating can be employed in pedestrian bridges and walkways, benefiting from its corrosion resistance and low maintenance needs. The visual appeal of FRP materials can also enhance the aesthetic quality of infrastructure.

4. Agricultural Applications Farmers utilize FRP mesh grating for building livestock platforms, storage facilities, and aquaculture systems. Its non-corrosive nature ensures that it withstands exposure to fertilizers and other harsh substances commonly found in agriculture.

Conclusion

FRP mesh grating stands out as a material that combines strength, versatility, and safety. As industries continue to seek innovative solutions to meet their operational needs, FRP mesh grating proves not just to be a reliable alternative, but a preferred choice in a variety of challenging environments. Its applications reflect an evolution in material science that enhances efficiency, safety, and sustainability across different sectors. As technological advancements continue to drive improvements in FRP mesh technology, we can expect even broader applications, further solidifying its place in modern engineering and construction.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

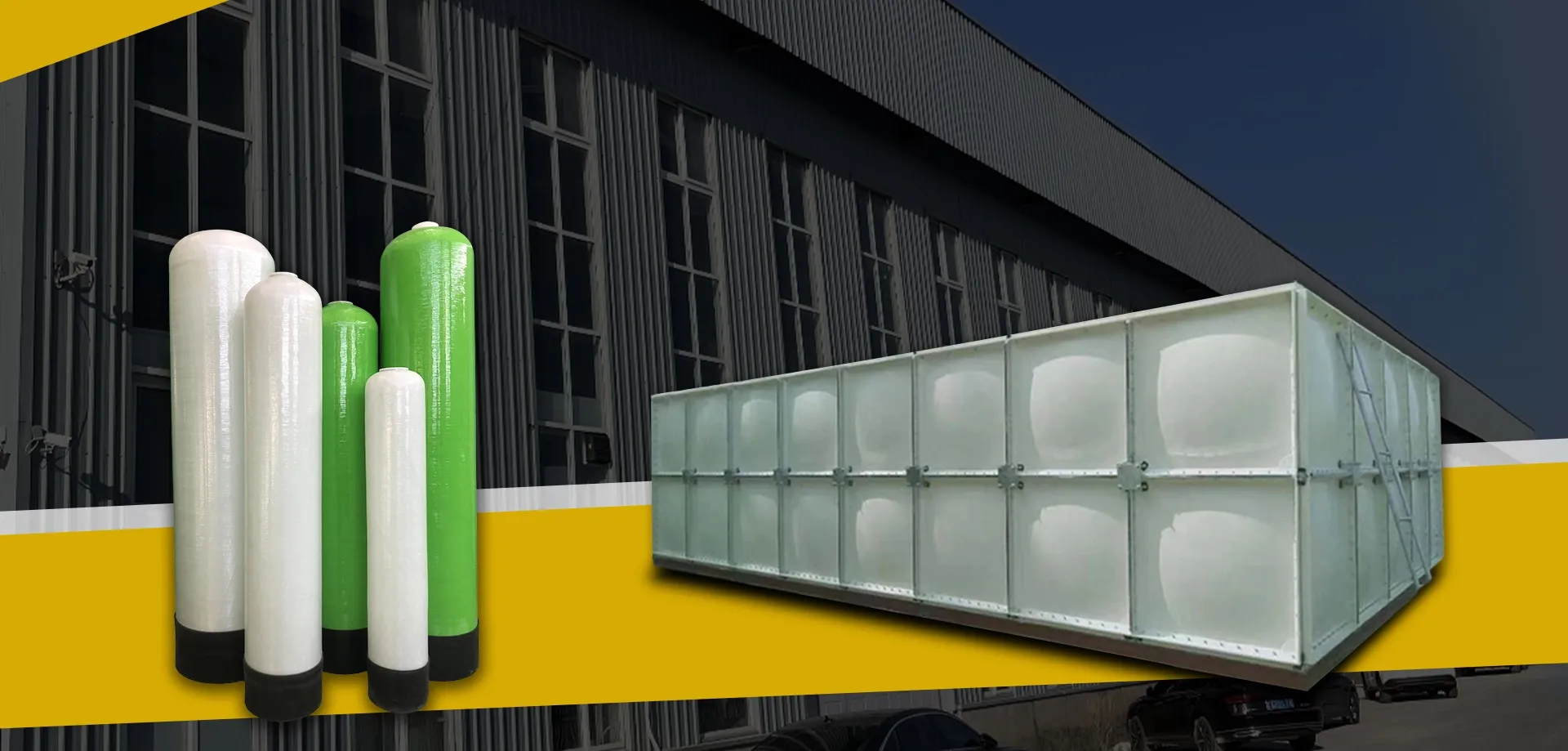

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024