loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Mesh Grating for Enhanced Structural Strength and Versatile Applications in Industrial Settings

The Versatility and Innovation of FRP Mesh Grating

In today's ever-evolving industrial landscape, the demand for efficient and durable materials has never been greater. One such innovative solution that has garnered significant attention is Fiber Reinforced Plastic (FRP) mesh grating. This advanced composite material offers a unique combination of strength, durability, and lightweight properties, making it an excellent choice for various applications across multiple industries.

FRP mesh grating is primarily composed of fiberglass reinforcements and a thermosetting resin, which together yield a product that is resistant to corrosion, UV degradation, and the effects of harsh chemicals. This resilience is particularly beneficial in environments where traditional materials, such as steel or wood, would quickly deteriorate. For instance, in wastewater treatment facilities or chemical processing plants, the exposure to corrosive substances can drastically reduce the lifespan of standard grating materials. However, with FRP mesh grating, companies can significantly extend the operational life of their structures while minimizing maintenance costs.

The Versatility and Innovation of FRP Mesh Grating

Safety is another critical aspect where FRP mesh grating excels. The non-slip surface provides excellent traction, reducing the risk of accidents in workplaces where moisture or chemicals could lead to slippery conditions. Additionally, the inherent properties of the material ensure that it does not conduct electricity, providing an extra layer of safety in electrical installations or environments with high-voltage equipment.

frp mesh grating

Environmental considerations are increasingly becoming a focal point in the material selection process for construction and industrial projects. FRP mesh grating is produced with sustainability in mind, and its long lifespan contributes to lower waste over time. Moreover, many manufacturers are adopting eco-friendly practices in their production processes, further minimizing the environmental impact. The recyclability of FRP materials at the end of their life cycle also aligns with the global movement toward sustainability and resource conservation.

The versatility of FRP mesh grating transcends industries. From petrochemical facilities and marine environments to food processing and commercial construction, the applications are virtually limitless. In the marine sector, for example, FRP is used for docks and bridges due to its resistance to saltwater and marine organisms. Within food processing plants, the ease of cleaning and the hygienic properties of FRP make it a preferred choice for flooring and platforms, ensuring compliance with health standards.

Moreover, FRP mesh grating can be customized according to specific project needs. From varying mesh sizes to different colors and finishes, manufacturers can tailor products to meet the aesthetic and functional requirements of any project. This customization capability allows companies to integrate FRP solutions seamlessly into their existing systems or design specifications.

In conclusion, the emergence of FRP mesh grating as a superior alternative to traditional materials is reshaping how we approach industrial and commercial projects. Its remarkable durability, lightweight properties, safety features, and environmental friendliness make it an ideal choice for a myriad of applications. As industries continue to seek innovative solutions to meet the challenges of modern construction and maintenance, FRP mesh grating stands out as a testament to the advancements in material science, poised to play an integral role in the future of various sectors. Embracing this technology not only enhances operational efficiency but also contributes to a more sustainable and safer working environment. As we move forward, it is clear that FRP mesh grating will remain at the forefront of industrial innovation.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

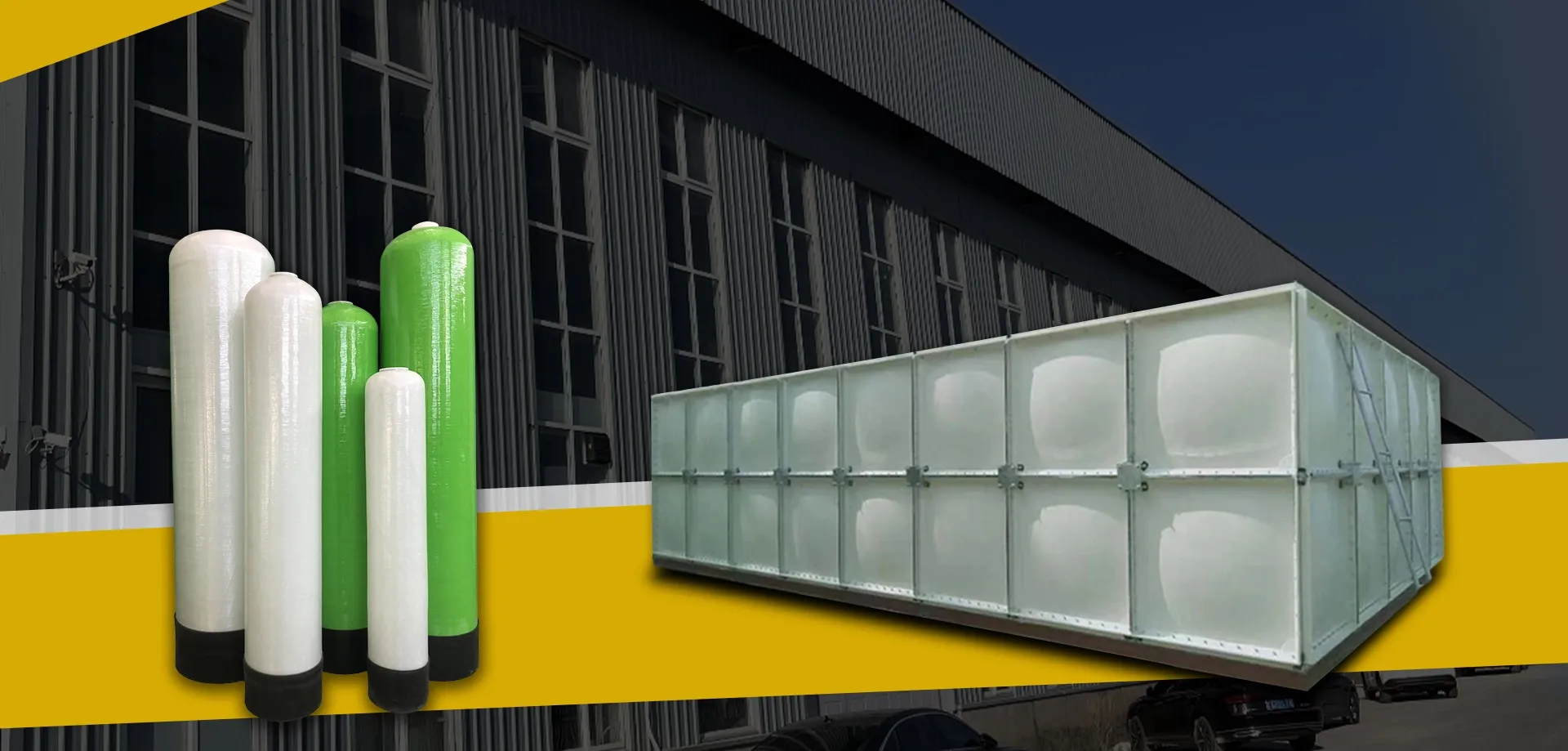

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024