loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Fiber Reinforced Plastic (FRP) mesh grating has revolutionized various industries due to its blend of strength and versatility. Unlike traditional materials such as metal or wood, FRP boasts an impressive resistance to harsh environmental conditions, including moisture, salt, and chemicals. This resilience makes it an ideal choice for industries like maritime, chemical processing, wastewater treatment, and even in architecturally demanding structures.

A key benefit of FRP mesh grating is its lightweight nature. This characteristic simplifies transportation and installation, leading to cost savings on equipment and labor. Moreover, despite its lightness, FRP exhibits a remarkable strength-to-weight ratio, providing superior load-bearing capabilities without compromising structural integrity. This strength ensures durability and long-term performance in heavy-duty applications.

Safety is paramount in any industrial or commercial setting, and FRP mesh grating excels here by offering a high degree of slip resistance. Its integrally molded-in grit surface ensures safe footing, significantly reducing the likelihood of workplace accidents. Additionally, FRP does not conduct electricity, making it a safer option in environments where there is potential exposure to electrical hazards.

The customization options with FRP mesh grating are vast. It can be tailored in a variety of thicknesses, configurations, and colors to meet the specific needs of any project. Customization extends to the apertures within the mesh, allowing for adequate drainage or ventilation, which is crucial in designing systems for defined operational requirements.

From a longevity perspective, FRP mesh grating is virtually maintenance-free. Its excellent corrosion resistance means that it does not rust or deteriorate easily, even in the most corrosive environments. This property not only extends the lifespan of the grating itself but also decreases the frequency and cost of maintenance and replacement.

frp mesh grating

Environmentally cognizant companies will appreciate that FRP mesh grating is often made from recycled materials, contributing to sustainability goals by reducing waste. Furthermore, the manufacturing process of FRP is frequently more energy-efficient than that of traditional materials, making it a more eco-friendly option.

In recent years, stringent industry standards and regulations have pushed manufacturers to ensure that their products meet high safety and quality benchmarks. FRP mesh grating often complies with international standards, guaranteeing not only top performance but also peace of mind regarding regulatory compliance.

The versatility of FRP mesh grating extends into architectural and aesthetic applications. Used as a design element, it adds a modern and industrial flair to interiors and exteriors, while also providing the practical benefits of reduced weight and enhanced durability.

For industries seeking robust, efficient, and cost-effective solutions, FRP mesh grating represents a forward-thinking choice. Its unmatched combination of strength, safety features, adaptability, and environmental consideration positions it as a product of exceptional value. As industries continue to evolve, leveraging innovative materials like FRP mesh grating is essential for maintaining competitive edge and operational excellence.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

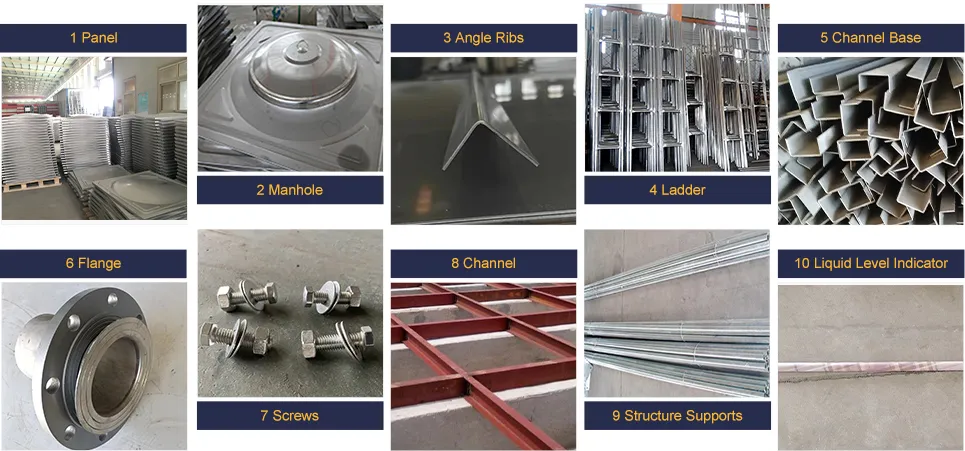

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024