loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

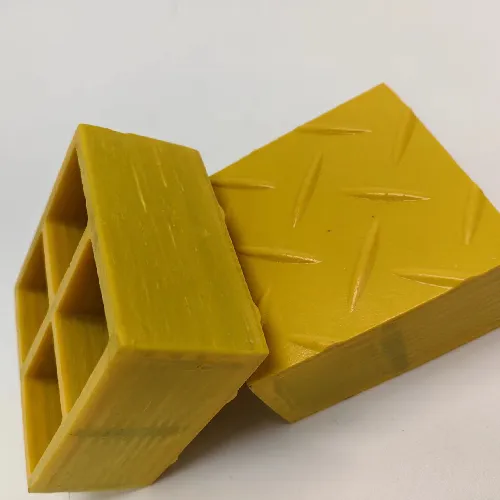

Enhance Safety with FRP Micro Mesh Grating Solutions

FRP micro mesh grating has emerged as a game-changer in industries requiring durable, lightweight, and corrosion-resistant flooring solutions. With years of industry experience, our team has witnessed the remarkable evolution of this material from a niche product to a universally appreciated solution across various sectors.

For industries prone to wet and harsh environments, such as marine, chemical, and food processing, the unique properties of FRP micro mesh grating offer a significant advantage over traditional materials like steel and wood. Unlike steel, FRP grating does not rust or corrode, making it a perfect solution for environments exposed to water or chemicals. This material ensures long-term reliability and minimal maintenance costs, thereby enhancing operational efficiency.

From a technical standpoint, FRP (fiber-reinforced plastic) consists of fiberglass reinforced with a resin matrix. This composition affords it superb strength-to-weight ratio—indeed, it is significantly lighter than metal alternatives, facilitating easier and more cost-effective installation. Handling these lightweight panels reduces labor costs and minimizes the need for heavy lifting machinery, ensuring a safer work environment.

Expertise in the field of industrial flooring reveals that safety is paramount. FRP micro mesh grating excels in providing a non-slip surface, essential for preventing workplace accidents. The intricate mesh design effectively channels away liquids, ensuring dry and safe walking surfaces even when exposed to spillages. Many businesses have already experienced a noticeable decline in work-related incidents after switching to FRP grating.

frp micro mesh grating

Authority in material science reaffirms the adaptability of FRP grating. Engineers appreciate its customization potential; it can be tailored to meet specific size, shape, and color requirements, allowing for seamless integration into existing infrastructure. Moreover, FRP's inherent UV resistance and fire retardant qualities further underscores its utility in demanding conditions, including outdoor and high-temperature environments.

Trustworthiness of FRP micro mesh grating extends beyond its physical properties. As sustainability becomes increasingly vital, it's noteworthy to consider the eco-friendly aspects of FRP materials. Many manufacturers now produce grating using recyclable resins, aiding industries in reducing their environmental footprint. This aligns with the growing emphasis on green building standards, ensuring not just compliance but leadership in environmental responsibility.

In conclusion, with FRP micro mesh grating, businesses gain a reliable, efficient, and sustainable flooring solution. Its balance of safety, adaptability, and durability meets the rigorous demands of contemporary industrial environments. Drawing from years of experience and technological understanding, transitioning to FRP grating presents an opportunity to revolutionize facility management and enhance operational safety and efficiency across the board. As this technology continues to advance, it remains at the forefront of industrial material innovation, trusted by experts worldwide for its proven performance and environmental resilience.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024