loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 13, 2025 09:19

Back to list

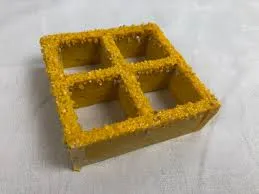

frp mini mesh grating

FRP mini mesh grating has rapidly become an essential component in various industrial and commercial applications, thanks to its multitude of benefits and versatile uses. Over the years, professionals have gained extensive experience and expertise in utilizing this material to enhance safety, durability, and operational efficiency. Here, we delve into the unique attributes and practical applications that set FRP mini mesh grating apart from other alternatives.

Beyond industrial applications, FRP mini mesh grating is making inroads into commercial and recreational spaces. Its aesthetic versatility allows it to be integrated into architectural designs without compromising functionality. Public venues such as parks, pedestrian bridges, and swimming pool decks are increasingly adopting FRP gratings owing to their slip-resistant surfaces, which enhance public safety without detracting from visual appeal. Moreover, the sustainability aspect of FRP mini mesh grating cannot be overlooked. As industries worldwide shift towards greener alternatives, FRP stands out as an environmentally friendly choice. The raw materials used in producing FRP grating are often derived from recycled sources, and its long life cycle reduces the frequency of replacements, minimizing waste. Authoritativeness and trustworthiness in the conversation around FRP mini mesh grating are reinforced by the wealth of case studies and industry reports endorsing its effectiveness. Leading authorities and industry professionals have rigorously tested and evaluated this material, establishing a repository of evidence that underscores its myriad benefits. These endorsements cement FRP grating’s position as a robust, reliable solution that meets the diverse needs of modern industrial, commercial, and public domains. In conclusion, the transformative impact of FRP mini mesh grating across various sectors is undeniable. Its plethora of benefits—ranging from corrosion resistance and safety enhancements to environmental sustainability and aesthetic flexibility—positions it as a superior choice over traditional materials. As more industries recognize and harness these advantages, FRP grating continues to redefine standards, ensuring it remains at the forefront of innovative engineering solutions. With proven expertise and growing trust in its capabilities, this material stands as a testament to the advancements in industrial technology and design.

Beyond industrial applications, FRP mini mesh grating is making inroads into commercial and recreational spaces. Its aesthetic versatility allows it to be integrated into architectural designs without compromising functionality. Public venues such as parks, pedestrian bridges, and swimming pool decks are increasingly adopting FRP gratings owing to their slip-resistant surfaces, which enhance public safety without detracting from visual appeal. Moreover, the sustainability aspect of FRP mini mesh grating cannot be overlooked. As industries worldwide shift towards greener alternatives, FRP stands out as an environmentally friendly choice. The raw materials used in producing FRP grating are often derived from recycled sources, and its long life cycle reduces the frequency of replacements, minimizing waste. Authoritativeness and trustworthiness in the conversation around FRP mini mesh grating are reinforced by the wealth of case studies and industry reports endorsing its effectiveness. Leading authorities and industry professionals have rigorously tested and evaluated this material, establishing a repository of evidence that underscores its myriad benefits. These endorsements cement FRP grating’s position as a robust, reliable solution that meets the diverse needs of modern industrial, commercial, and public domains. In conclusion, the transformative impact of FRP mini mesh grating across various sectors is undeniable. Its plethora of benefits—ranging from corrosion resistance and safety enhancements to environmental sustainability and aesthetic flexibility—positions it as a superior choice over traditional materials. As more industries recognize and harness these advantages, FRP grating continues to redefine standards, ensuring it remains at the forefront of innovative engineering solutions. With proven expertise and growing trust in its capabilities, this material stands as a testament to the advancements in industrial technology and design.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024