loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 12, 2025 21:21

Back to list

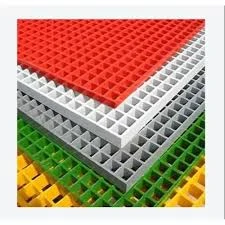

frp pultruded gratings

FRP moulded gratings, constructed from fibre-reinforced plastic, stand as a revolutionary solution in industrial flooring and structural applications. Their integration into various sectors has highlighted not just their utility but also the profound benefits they deliver in terms of durability, safety, and economic viability.

The versatility of FRP moulded gratings cannot be overstated. They are available in a variety of sizes, thicknesses, and panel configurations, facilitating customized solutions tailored to specific project needs. This flexibility allows architects and engineers to design with creativity and precision, ensuring functional and aesthetic requirements are fully met. Expert testimonies from industry leaders underscore the advantages of FRP grating implementations. Real-world feedback from on-site engineers and facility managers reiterates the product’s reliability and effectiveness in enhancing operational workflows. Such endorsements solidify the credibility of FRP moulded gratings as a go-to choice in industrial applications. In addition, the environmentally friendly aspect of FRP moulded gratings cannot be overlooked. As global attention pivots towards sustainability, the GRP gratings' long lifespan and non-toxicity during production and use align with ecological objectives, making them an environmentally responsible option for modern industries. As industries face increasing demands for both performance and sustainability, FRP moulded gratings stand out as a robust, reliable, and sustainable choice. Their balance of strength, durability, and low maintenance makes them indispensable in forward-thinking industrial design. As more facilities recognize the myriad advantages of FRP gratings, their application continues to broaden, underscoring their role as a pivotal component in the evolution of safe and durable infrastructure solutions. Thus, in the realm of industrial solutions, FRP moulded gratings not only fulfill the immediate needs but also anticipate future challenges, ready to provide outstanding performance across a multitude of demanding environments. Their role in the future of industrial materials is not just advantageous, it’s essential.

The versatility of FRP moulded gratings cannot be overstated. They are available in a variety of sizes, thicknesses, and panel configurations, facilitating customized solutions tailored to specific project needs. This flexibility allows architects and engineers to design with creativity and precision, ensuring functional and aesthetic requirements are fully met. Expert testimonies from industry leaders underscore the advantages of FRP grating implementations. Real-world feedback from on-site engineers and facility managers reiterates the product’s reliability and effectiveness in enhancing operational workflows. Such endorsements solidify the credibility of FRP moulded gratings as a go-to choice in industrial applications. In addition, the environmentally friendly aspect of FRP moulded gratings cannot be overlooked. As global attention pivots towards sustainability, the GRP gratings' long lifespan and non-toxicity during production and use align with ecological objectives, making them an environmentally responsible option for modern industries. As industries face increasing demands for both performance and sustainability, FRP moulded gratings stand out as a robust, reliable, and sustainable choice. Their balance of strength, durability, and low maintenance makes them indispensable in forward-thinking industrial design. As more facilities recognize the myriad advantages of FRP gratings, their application continues to broaden, underscoring their role as a pivotal component in the evolution of safe and durable infrastructure solutions. Thus, in the realm of industrial solutions, FRP moulded gratings not only fulfill the immediate needs but also anticipate future challenges, ready to provide outstanding performance across a multitude of demanding environments. Their role in the future of industrial materials is not just advantageous, it’s essential.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024