loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 10, 2025 10:14

Back to list

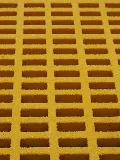

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Fiberglass Reinforced Plastic (FRP) platform grating is revolutionizing industries worldwide by offering an unparalleled combination of safety, durability, and cost-effectiveness. This innovative product is increasingly substituting traditional materials like steel and wood in various applications. Its unique properties cater to industries demanding high-performance solutions, particularly those exposed to extreme environmental conditions.

Trustworthiness in FRP platform grating comes from real-world applications and feedback from industry leaders who have adopted this technology. Companies report not only cost savings in terms of reduced maintenance and installation expenses but also enhanced employee safety and satisfaction. The anti-slip surfacing of the grating offers excellent traction, reducing the risk of workplace accidents. In environments where safety is paramount, such as oil and gas platforms, this feature proves invaluable. Additionally, FRP platform grating offers excellent versatility in design and application. Available in various thicknesses, sizes, and shapes, it can be customized to meet specific project requirements—from pedestrian walkways in public spaces to complex industrial platforms. The ease of fabrication means that modifications and adjustments can be made on-site without the need for specialized tools, a significant advantage during installations or urgent repairs. The sustainability aspect of FRP platform grating also cannot be understated. As industries move towards greener practices, the production of FRP requires less energy and raw materials compared to traditional alternatives. It contributes to a decrease in the overall carbon footprint of a project. Furthermore, the long lifecycle of the grating ensures that replacements are minimal, reducing waste and environmental impact over time. In summary, FRP platform grating represents a groundbreaking advancement in industrial flooring solutions. Its benefits are rooted in its resilient performance in harsh environments, robust construction, compliance with strict safety standards, and proven track record in enhancing occupational safety. As industries continue to evolve, adopting materials that promote sustainability and efficiency, FRP platform grating is set to play a pivotal role in shaping the future of industrial infrastructure. This product not only meets but exceeds the demands of contemporary industrial challenges, establishing itself as a cornerstone in the pursuit of optimized, safe, and cost-effective industrial operations.

Trustworthiness in FRP platform grating comes from real-world applications and feedback from industry leaders who have adopted this technology. Companies report not only cost savings in terms of reduced maintenance and installation expenses but also enhanced employee safety and satisfaction. The anti-slip surfacing of the grating offers excellent traction, reducing the risk of workplace accidents. In environments where safety is paramount, such as oil and gas platforms, this feature proves invaluable. Additionally, FRP platform grating offers excellent versatility in design and application. Available in various thicknesses, sizes, and shapes, it can be customized to meet specific project requirements—from pedestrian walkways in public spaces to complex industrial platforms. The ease of fabrication means that modifications and adjustments can be made on-site without the need for specialized tools, a significant advantage during installations or urgent repairs. The sustainability aspect of FRP platform grating also cannot be understated. As industries move towards greener practices, the production of FRP requires less energy and raw materials compared to traditional alternatives. It contributes to a decrease in the overall carbon footprint of a project. Furthermore, the long lifecycle of the grating ensures that replacements are minimal, reducing waste and environmental impact over time. In summary, FRP platform grating represents a groundbreaking advancement in industrial flooring solutions. Its benefits are rooted in its resilient performance in harsh environments, robust construction, compliance with strict safety standards, and proven track record in enhancing occupational safety. As industries continue to evolve, adopting materials that promote sustainability and efficiency, FRP platform grating is set to play a pivotal role in shaping the future of industrial infrastructure. This product not only meets but exceeds the demands of contemporary industrial challenges, establishing itself as a cornerstone in the pursuit of optimized, safe, and cost-effective industrial operations.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024