loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp post

Exploring the Power of FRP Strength, Versatility, and Future Prospects

Fiber-Reinforced Polymer (FRP) has gained significant attention in various industries due to its unique blend of properties. Composed of a polymer matrix reinforced with fibers, typically glass, carbon, or aramid, FRP materials exhibit remarkable strength-to-weight ratios, exceptional resistance to corrosion, and excellent durability. These attributes make FRP an invaluable choice in applications ranging from construction and aerospace to automotive and marine industries.

.

In addition to being lightweight, FRP materials exhibit outstanding strength characteristics. They can withstand substantial loads and resist bending and cracking better than many conventional materials. This strength, combined with their resistance to environmental degradation, makes FRP an ideal choice for applications in harsh environments. For example, in civil engineering, FRP is increasingly used in the reinforcement of bridge structures and buildings, providing enhanced durability and longevity without the need for extensive maintenance.

frp post

Corrosion resistance is another vital advantage of FRP. In sectors like construction and marine industries, where materials are often exposed to moisture, salt, and other corrosive agents, FRP can significantly extend service life. This property reduces maintenance costs and downtime, making it a cost-effective solution over the long term. As cities continue to grapple with aging infrastructure, incorporating FRP as a repair and retrofitting solution offers a promising pathway to enhance structural integrity and safety.

The versatility of FRP is also worth noting. Manufacturers can tailor the properties of FRP composites by varying the type and orientation of the fibers used, the type of polymer matrix, and the manufacturing process. This customization allows engineers and designers to optimize FRP materials for specific applications, whether they need lightweight components for an aircraft or high-strength structures for a bridge.

Looking ahead, the future of FRP seems bright. As technology advances, new manufacturing processes, such as 3D printing with FRP composites, are emerging, providing even greater design flexibility and efficiency. Additionally, the rising trend toward sustainability in material science is leading to a greater focus on eco-friendly manufacturing practices, including the development of bio-based polymers and recycling methods for FRP materials.

In conclusion, Fiber-Reinforced Polymer stands as a groundbreaking material that exemplifies the intersection of innovation and practicality. Its unique properties, including lightweight, high strength, corrosion resistance, and versatility, position it as a superior choice across various industries. As research continues and the demand for sustainable solutions grows, FRP is poised to revolutionize traditional practices, paving the way for safer and more efficient applications in the modern world.

-

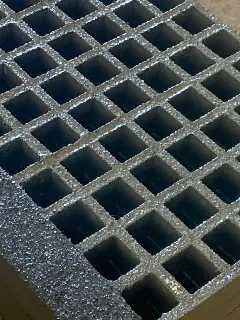

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024