loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 13, 2025 10:30

Back to list

frp pressure tank

In today's rapidly evolving industrial landscape, the demand for durable and reliable storage solutions has never been greater. At the forefront of meeting these demands are fibreglass-reinforced plastic (FRP) pressure tanks. This technology, with its superior properties and practical applications, is gaining traction across a variety of industries. To understand the full potential and appeal of FRP pressure tanks, it is essential to delve into the experience, expertise, authoritativeness, and trustworthiness that underpin their usage.

Trustworthiness in FRP pressure tank solutions is also anchored in long-standing successful implementation across industries. Real-world applications serve as powerful testimonials to their efficacy. Feedback from field operations consistently highlights the durability, minimal maintenance requirements, and cost-efficiency of FRP tanks. Case studies from leading companies that have transitioned to FRP solutions often report increased operational efficiency and a significant reduction in lifecycle costs, reinforcing the trust businesses can place in this technology. Moreover, FRP pressure tanks contribute positively to environmental sustainability — a compelling factor for businesses conscious of their ecological impact. Their lightweight nature not only reduces transportation energy consumption but also requires less energy for installation compared to conventional metal tanks. Their long lifespan negates the frequency of replacements, thereby reducing waste and conserving resources. In conclusion, fibreglass-reinforced plastic pressure tanks represent a blend of technological innovation and practical efficiency. With superior corrosion resistance, customization capabilities, and adherence to global standards, they stand as a testament to engineering excellence. As industries progressively lean toward sustainable and reliable operations, FRP pressure tanks will continue to play a pivotal role in meeting these objectives. For businesses seeking to optimize their storage solutions, investing in FRP technology is not just an option but a strategic initiative aligned with future-focused operational models.

Trustworthiness in FRP pressure tank solutions is also anchored in long-standing successful implementation across industries. Real-world applications serve as powerful testimonials to their efficacy. Feedback from field operations consistently highlights the durability, minimal maintenance requirements, and cost-efficiency of FRP tanks. Case studies from leading companies that have transitioned to FRP solutions often report increased operational efficiency and a significant reduction in lifecycle costs, reinforcing the trust businesses can place in this technology. Moreover, FRP pressure tanks contribute positively to environmental sustainability — a compelling factor for businesses conscious of their ecological impact. Their lightweight nature not only reduces transportation energy consumption but also requires less energy for installation compared to conventional metal tanks. Their long lifespan negates the frequency of replacements, thereby reducing waste and conserving resources. In conclusion, fibreglass-reinforced plastic pressure tanks represent a blend of technological innovation and practical efficiency. With superior corrosion resistance, customization capabilities, and adherence to global standards, they stand as a testament to engineering excellence. As industries progressively lean toward sustainable and reliable operations, FRP pressure tanks will continue to play a pivotal role in meeting these objectives. For businesses seeking to optimize their storage solutions, investing in FRP technology is not just an option but a strategic initiative aligned with future-focused operational models.

Share

Latest news

-

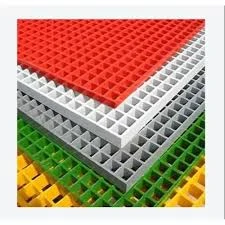

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024