loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp pressure vessel

Understanding FRP Pressure Vessels The Material of the Future

In recent years, the use of Fiber Reinforced Polymer (FRP) materials in pressure vessels has gained momentum across various industries. Known for their exceptional properties, FRP pressure vessels are revolutionizing how we think about storage and transport of gases and liquids, particularly in demanding environments.

What are FRP Pressure Vessels?

FRP pressure vessels are cylindrical containers made from a composite material that consists of a polymer matrix reinforced with fibers, typically glass or carbon. These vessels are designed to withstand high pressure and are commonly used for storing gases like oxygen, hydrogen, and natural gas, as well as liquids, including chemicals and wastewater. The combination of strength and lightweight nature of FRP makes these vessels an attractive alternative to traditional materials such as metals.

Advantages of FRP Pressure Vessels

1. Corrosion Resistance One of the most significant advantages of FRP is its inherent resistance to corrosion. Traditional metal vessels, especially those used in chemical processes, often succumb to rust and degradation over time. FRP, on the other hand, can withstand hostile environments and aggressive chemicals without compromising its structural integrity.

2. Lightweight FRP pressure vessels are significantly lighter than their metal counterparts. This feature not only makes transportation easier but also reduces installation costs. The lighter weight is particularly beneficial in applications where weight constraints are critical, such as in aerospace or offshore operations.

3. Design Flexibility FRP is highly customizable, allowing manufacturers to create pressure vessels in various shapes and sizes tailored to specific applications. This design flexibility is complemented by the ability to incorporate different fiber types and orientations to enhance the vessel's mechanical properties.

4. Thermal Insulation FRP has better insulation properties compared to metals, which helps maintain temperature within the vessel more effectively. This property is especially crucial in industries where temperature control is vital, such as in cryogenic storage.

frp pressure vessel

5. Cost-Effectiveness Although the initial investment in FRP technology can be higher than traditional materials, the long-term savings due to reduced maintenance, lower energy costs for heating or cooling, and extended lifespan make FRP pressure vessels a cost-effective choice.

Applications of FRP Pressure Vessels

FRP pressure vessels find applications in various sectors including the oil and gas industry, water treatment facilities, and chemical processing plants. In the oil and gas sector, they are utilized for transporting and storing hydrogen and natural gas. Their resistance to corrosion and extreme temperatures makes them ideal for offshore platforms.

In water treatment, FRP vessels are extensively used in filtration systems. Their ability to withstand harsh chemicals used in water treatment processes makes them a preferred option over traditional materials. Additionally, the aerospace industry is exploring the use of FRP for fuel storage tanks due to their lightweight properties and durability.

Challenges and Future Prospects

Despite their numerous advantages, FRP pressure vessels also face challenges. The manufacturing process can be complex and requires skilled labor, which may limit adoption in some regions. Furthermore, there are ongoing concerns about the long-term durability of the polymer matrix under extreme conditions.

However, with advancements in materials science and manufacturing technologies, the future of FRP pressure vessels looks promising. Research is being conducted to enhance the mechanical properties and resistance to environmental factors of FRP materials, thereby broadening their applicability.

Conclusion

FRP pressure vessels represent a significant advancement in pressure vessel technology, offering numerous advantages over traditional materials. Their lightweight, corrosion-resistant, and customizable properties make them suitable for a broad range of applications. As industries continue to seek efficient and sustainable solutions, FRP pressure vessels are set to play a crucial role in the future of material storage and transportation. As research and innovation in this field progress, we can anticipate even greater improvements in performance, safety, and cost-effectiveness, positioning FRP as the material of choice in pressure vessel applications.

-

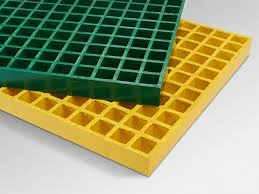

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024