loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp pressure vessel price

Understanding the Pricing Factors of FRP Pressure Vessels

Fiberglass Reinforced Plastic (FRP) pressure vessels have increasingly become a popular choice in various industries due to their corrosion resistance, lightweight, and high strength-to-weight ratio. As industries seek cost-effective yet durable solutions for transporting and storing liquids and gases, the demand for FRP pressure vessels has surged. However, potential buyers often encounter a wide range of prices for these specialized pieces of equipment. Understanding the factors that influence the pricing of FRP pressure vessels is crucial for making informed purchasing decisions.

Material Composition

One of the primary determinants of the cost of FRP pressure vessels is the raw materials used in their fabrication. The quality and type of fiberglass, resin, and additional materials such as fillers and additives can significantly affect the price. Higher quality resins, for instance, can improve the vessel's durability and resistance to chemicals, but they also come at a premium. Additionally, advancements in material technology and preferences for specialized resins such as vinylester or epoxy can further contribute to pricing variations.

Manufacturing Process

The manufacturing process used to create FRP pressure vessels also plays a crucial role in determining their costs. There are various techniques employed in the production of these vessels, including filament winding, hand lay-up, and spray-up methods. Each method has its advantages and disadvantages, impacting both the cost and the performance of the finished product. For example, filament winding provides superior strength and consistency but requires more sophisticated equipment and a higher initial investment, leading to increased prices.

Size and Capacity

The size and capacity of the FRP pressure vessel are direct factors affecting its price. Larger vessels require more materials, more labor, and potentially more complex manufacturing processes. As a result, the cost increase is often nonlinear; doubling the size of a vessel does not simply double the price due to the various economies (or diseconomies) of scale encountered in production. Potential buyers should assess their specific needs to avoid overpaying for unnecessary capacity.

frp pressure vessel price

Certifications and Compliance

In many industries, pressure vessels must meet stringent regulatory standards and certifications, such as ASME (American Society of Mechanical Engineers) and API (American Petroleum Institute) standards. Achieving and maintaining these certifications not only requires additional testing and quality assurance protocols but also adds to the overall manufacturing costs. Therefore, vessels that comply with rigorous standards will typically command higher prices due to the assurance of safety and reliability they provide.

Customization and Design Complexity

Customization is another critical aspect affecting the price of FRP pressure vessels. Standard models generally come with a lower price tag as they can be produced in bulk without customization. However, if a buyer requires particular sizes, shapes, or features, such as specific fittings or coatings, this customization can lead to increased labor costs and production times, resulting in a higher price. The complexity of the design also plays a role; intricate designs require more engineering resources, thus increasing costs.

Market Dynamics and Demand

Finally, market dynamics and demand factors influence the pricing of FRP pressure vessels. Economic conditions, supply chain constraints, and fluctuations in raw material costs can all lead to volatile pricing. During periods of high demand, such as booms in the oil and gas sector or water treatment industries, prices may rise due to increased competition for resources. Conversely, during economic downturns, prices may stabilize or even drop as demand wanes.

Conclusion

In conclusion, several interconnected factors influence the pricing of FRP pressure vessels. Understanding the implications of materials, manufacturing processes, size, regulatory compliance, customization, and market dynamics is vital for making informed purchases. Potential buyers should conduct thorough research, comparing options and noting the specific needs of their applications to ensure they receive the best value. While FRP pressure vessels may sometimes come with a higher upfront cost, the long-term benefits of durability, resistance, and safety can justify the investment, leading to significant savings over time. As the industry continues to evolve, keeping abreast of these variables will empower buyers to make the best decisions for their operational needs.

-

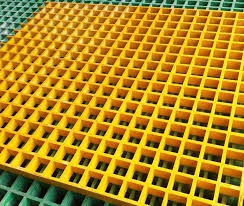

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024