loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Advanced Composite Materials for High-Performance Pressure Vessels in Industrial Applications

Understanding FRP Pressure Vessels Applications and Advantages

Fiber-Reinforced Plastic (FRP) pressure vessels are gaining prominence in various industries due to their unique properties and advantages over traditional materials like steel or aluminum. These vessels, composed of a polymer matrix reinforced with fibers (usually glass or carbon), have transformed the way pressure-related applications are handled.

Properties of FRP Pressure Vessels

One of the most significant properties of FRP is its high strength-to-weight ratio. Compared to conventional metals, FRP is considerably lighter, which makes it easier to handle, transport, and install. This characteristic is particularly beneficial in sectors where weight reduction can lead to substantial cost savings and increased efficiency. Furthermore, FRP is naturally corrosion-resistant, making it suitable for harsh chemical environments where traditional vessels might deteriorate.

Another essential feature of FRP pressure vessels is their design flexibility. Manufacturers can mold FRP into various shapes and sizes, allowing for customized solutions tailored to specific applications. This versatility enables industries to optimize their systems for particular operational requirements, leading to enhanced performance and reliability.

Applications of FRP Pressure Vessels

The applications of FRP pressure vessels are diverse, spanning multiple industries including chemical processing, oil and gas, water treatment, and aerospace. In the chemical industry, FRP vessels are extensively used for storing and transporting aggressive chemicals due to their resistance to corrosion and degradation. Similarly, in the oil and gas sector, these vessels are used for various applications, including storage tanks and pipes, where lightweight materials are essential to reduce operational costs and improve safety.

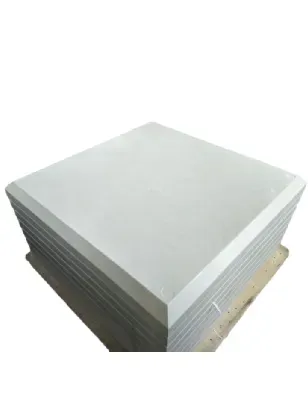

frp pressure vessels

Moreover, the growing emphasis on sustainable practices has spurred the adoption of FRP pressure vessels in water treatment and conservation. Their ability to withstand corrosive materials allows them to be employed in various processes, enhancing the efficiency of water management systems while minimizing environmental impact.

Advantages of Using FRP Pressure Vessels

The advantages of using FRP pressure vessels are numerous. First, their lightweight nature results in reduced transportation and installation costs. Second, the longevity and durability of FRP can lead to lower maintenance and replacement costs over time. Additionally, the insulating properties of FRP can help in thermal management, reducing energy consumption in processes dependent on temperature control.

Furthermore, the inherent design flexibility of FRP allows for complex geometries that can meet specific engineering demands. This adaptability, combined with the material's capability to withstand extreme pressures and temperatures, makes FRP pressure vessels a compelling choice for various engineering applications.

Conclusion

In summary, FRP pressure vessels represent a significant advancement in material science, offering numerous benefits that enhance operational efficiency and safety across multiple industries. Their lightweight, corrosion-resistant properties, combined with design flexibility and cost-effectiveness, position them as a vital component in the future of pressure containment systems. As industries continue to seek innovative solutions to meet their evolving needs, FRP pressure vessels are likely to play an increasingly crucial role in optimizing performance while minimizing environmental impact.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024