loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 21, 2025 00:33

Back to list

frp pressure vessels

Fiberglass Reinforced Plastic (FRP) pressure vessels represent an innovative shift in engineering and design, offering unparalleled benefits across multiple industries due to their exceptional strength, durability, and versatility. These pressure vessels, crafted from composite materials, are increasingly recognized for their ability to withstand harsh environmental conditions and corrosive substances.

The trustworthiness of FRP pressure vessels is well documented through industry certifications and compliance with international standards. These vessels are subjected to stringent testing during development, ensuring they conform to safety and performance benchmarks. Industries can have confidence in deploying FRP pressure vessels, knowing they meet the necessary regulatory requirements and have proven performance records in demanding scenarios. In terms of experience, numerous case studies and real-world applications underscore the value of integrating FRP pressure vessels into industrial operations. Companies that have transitioned from traditional materials to FRP have reported marked improvements in efficiency and reductions in maintenance downtime. The consistent feedback from industry leaders highlights not only the operational benefits but also a favorable return on investment, emphasizing that FRP pressure vessels are not just a technological advancement but a strategic business decision. Moreover, global trends indicate a growing demand for sustainable and efficient industrial solutions, positioning FRP pressure vessels at the forefront of this evolution. As industries aim to reduce their carbon footprint and enhance energy efficiency, the lightweight and durable nature of FRP make it an attractive option. These vessels contribute to sustainability goals by minimizing material usage and extending service life, which in turn decreases the frequency of replacements and resource consumption. In conclusion, FRP pressure vessels represent a blend of cutting-edge technology and practical application, offering industries an advanced, reliable, and economically sound option for managing high-pressure situations. With their robust construction, resistance to environmental challenges, and ability to be customized for specific needs, FRP pressure vessels stand as a testament to the future of industrial equipment—a future where efficiency, sustainability, and performance are perfectly balanced.

The trustworthiness of FRP pressure vessels is well documented through industry certifications and compliance with international standards. These vessels are subjected to stringent testing during development, ensuring they conform to safety and performance benchmarks. Industries can have confidence in deploying FRP pressure vessels, knowing they meet the necessary regulatory requirements and have proven performance records in demanding scenarios. In terms of experience, numerous case studies and real-world applications underscore the value of integrating FRP pressure vessels into industrial operations. Companies that have transitioned from traditional materials to FRP have reported marked improvements in efficiency and reductions in maintenance downtime. The consistent feedback from industry leaders highlights not only the operational benefits but also a favorable return on investment, emphasizing that FRP pressure vessels are not just a technological advancement but a strategic business decision. Moreover, global trends indicate a growing demand for sustainable and efficient industrial solutions, positioning FRP pressure vessels at the forefront of this evolution. As industries aim to reduce their carbon footprint and enhance energy efficiency, the lightweight and durable nature of FRP make it an attractive option. These vessels contribute to sustainability goals by minimizing material usage and extending service life, which in turn decreases the frequency of replacements and resource consumption. In conclusion, FRP pressure vessels represent a blend of cutting-edge technology and practical application, offering industries an advanced, reliable, and economically sound option for managing high-pressure situations. With their robust construction, resistance to environmental challenges, and ability to be customized for specific needs, FRP pressure vessels stand as a testament to the future of industrial equipment—a future where efficiency, sustainability, and performance are perfectly balanced.

Share

Next:

Latest news

-

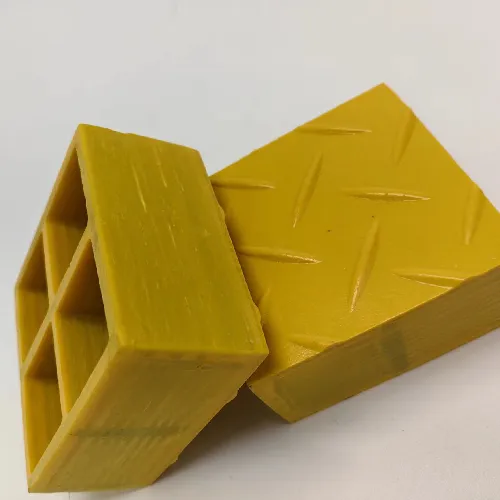

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

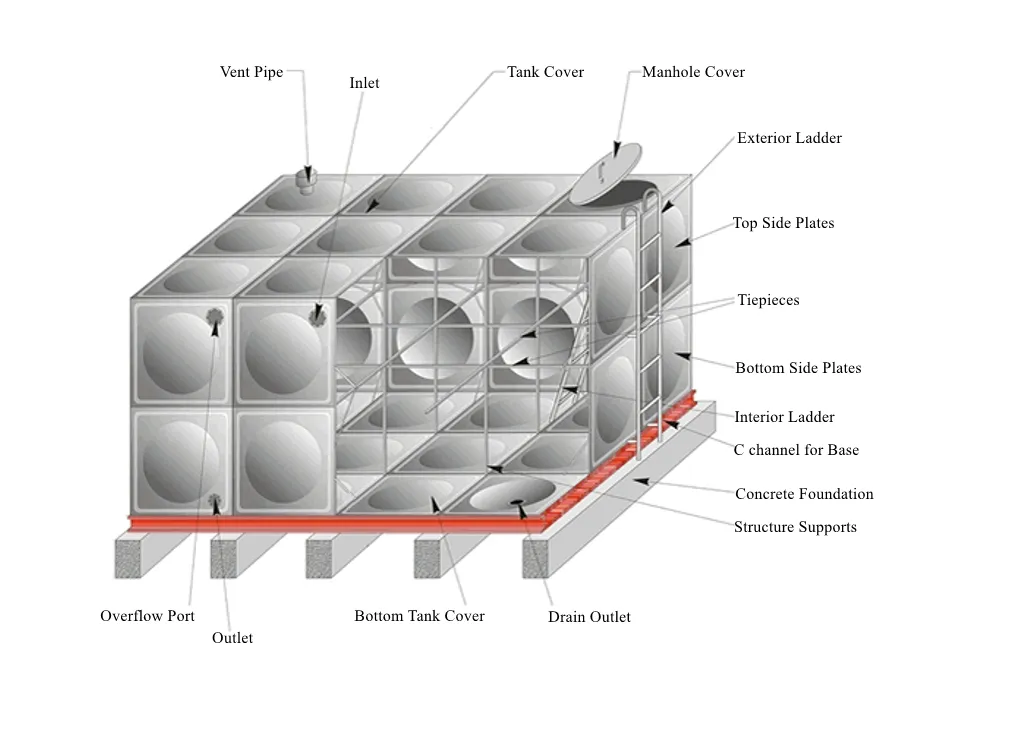

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024