loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 01, 2025 06:05

Back to list

High Strength FRP Pultruded Profile Fiberglass I Beam for Construction

FRP profiles have revolutionized industries due to their high strength-to-weight ratio, corrosion resistance, and adaptability. These profiles, used in numerous applications such as construction, automotive, and marine sectors, showcase the unparalleled potential of fiber-reinforced polymers (FRP).

Trustworthiness of FRP profiles is backed by real-world applications and certification by international standards. Given that industries require materials to meet stringent safety and quality criteria, FRP profiles are regularly vetted against ISO and ASTM standards, ensuring they meet industry-specific performance benchmarks. Moreover, trust is built through transparent manufacturing practices and rigorous third-party testing, providing stakeholders with quantifiable data on the profiles' capabilities and adherence to safety protocols. In the world of product innovation, the role of FRP profiles cannot be understated. These products are not just alternatives to traditional materials but are often preferred due to their lightweight, high-strength characteristics, and non-conductive nature, making them ideal for sectors dealing with electrical hazards or weight limitations. Industries like aerospace benefit from these profiles by achieving significant weight reductions, thus improving fuel efficiency without compromising on structural integrity. FRP profiles are constantly evolving with advancements in fiber and resin technology. Research into bio-based resins and recyclable fibers marks a promising shift towards sustainable material sciences, paving the way for environmentally friendly alternatives without sacrificing performance. This progress not only enhances the profiles' application range but also aligns with global sustainability goals, appealing to environmentally conscious consumers and industries alike. In conclusion, FRP profiles represent an intersection of innovation, reliability, and sustainability. Their adoption across various sectors underscores their reputation as a versatile and trusted material. As technology progresses, the continued development and application of FRP profiles promise to redefine the parameters of modern engineering and construction, delivering solutions that are as robust as they are transformative.

Trustworthiness of FRP profiles is backed by real-world applications and certification by international standards. Given that industries require materials to meet stringent safety and quality criteria, FRP profiles are regularly vetted against ISO and ASTM standards, ensuring they meet industry-specific performance benchmarks. Moreover, trust is built through transparent manufacturing practices and rigorous third-party testing, providing stakeholders with quantifiable data on the profiles' capabilities and adherence to safety protocols. In the world of product innovation, the role of FRP profiles cannot be understated. These products are not just alternatives to traditional materials but are often preferred due to their lightweight, high-strength characteristics, and non-conductive nature, making them ideal for sectors dealing with electrical hazards or weight limitations. Industries like aerospace benefit from these profiles by achieving significant weight reductions, thus improving fuel efficiency without compromising on structural integrity. FRP profiles are constantly evolving with advancements in fiber and resin technology. Research into bio-based resins and recyclable fibers marks a promising shift towards sustainable material sciences, paving the way for environmentally friendly alternatives without sacrificing performance. This progress not only enhances the profiles' application range but also aligns with global sustainability goals, appealing to environmentally conscious consumers and industries alike. In conclusion, FRP profiles represent an intersection of innovation, reliability, and sustainability. Their adoption across various sectors underscores their reputation as a versatile and trusted material. As technology progresses, the continued development and application of FRP profiles promise to redefine the parameters of modern engineering and construction, delivering solutions that are as robust as they are transformative.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

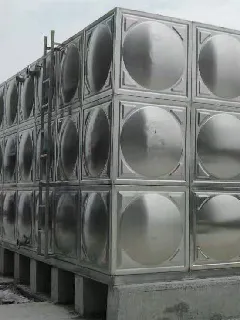

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024