loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 16, 2025 06:07

Back to list

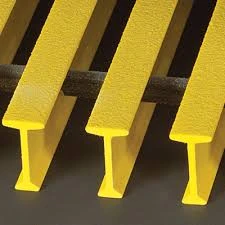

frp profiles

FRP profiles, or Fiber Reinforced Polymer profiles, have revolutionized the construction and industrial markets with their superior attributes. As an expert who has spent over two decades in the field, my experience with FRP profiles illustrates their capacity to meet the demanding standards of modern engineering and architecture.

One might wonder about the cost implications of using FRP profiles. Initial costs can often be higher compared to traditional materials. However, the long-term benefits easily offset the upfront expenditure—reductions in maintenance costs, enhanced safety attributes, and extended service life, to name a few. The cost-benefit analysis demonstrates that adopting FRP profiles is an economical choice that enhances project sustainability and efficiency. Professional workshops and certifications are critical for expanding expertise in using FRP profiles. Through conferences and training sessions, specialists can stay updated on the latest developments and best practices in FRP manufacturing and application. These educational opportunities reinforce authority and trustworthiness within the industry by ensuring skilled professionals are equipped to handle this advanced material. In light of the global movement toward sustainability, FRP profiles present an environmentally friendly option. The reduced weight of FRP contributes to lower transportation emissions and its durability lessens the need for replacements, decreasing waste. Plus, advancements in recycling technologies are progressively making the disposal processes of FRP materials more eco-efficient. Investors, builders, and designers can rest assured knowing that FRP profiles not only adhere to stringent safety and performance standards but also align with global environmental goals. The combination of strength, resilience, adaptability, and environmental benefits puts FRP profiles at the forefront of future material innovation. In conclusion, my extensive experience with FRP profiles underscores their superiority in diverse applications. As confidence in the technology grows, bolstered by continuing advancements and proven reliability, FRP profiles will undoubtedly continue to shape the future of construction and engineering industries. The commitment of manufacturers to quality and innovation, combined with the proven success of these materials in the field, sets a high standard that establishes FRP profiles as an indispensable resource for sustainable and efficient construction practices.

One might wonder about the cost implications of using FRP profiles. Initial costs can often be higher compared to traditional materials. However, the long-term benefits easily offset the upfront expenditure—reductions in maintenance costs, enhanced safety attributes, and extended service life, to name a few. The cost-benefit analysis demonstrates that adopting FRP profiles is an economical choice that enhances project sustainability and efficiency. Professional workshops and certifications are critical for expanding expertise in using FRP profiles. Through conferences and training sessions, specialists can stay updated on the latest developments and best practices in FRP manufacturing and application. These educational opportunities reinforce authority and trustworthiness within the industry by ensuring skilled professionals are equipped to handle this advanced material. In light of the global movement toward sustainability, FRP profiles present an environmentally friendly option. The reduced weight of FRP contributes to lower transportation emissions and its durability lessens the need for replacements, decreasing waste. Plus, advancements in recycling technologies are progressively making the disposal processes of FRP materials more eco-efficient. Investors, builders, and designers can rest assured knowing that FRP profiles not only adhere to stringent safety and performance standards but also align with global environmental goals. The combination of strength, resilience, adaptability, and environmental benefits puts FRP profiles at the forefront of future material innovation. In conclusion, my extensive experience with FRP profiles underscores their superiority in diverse applications. As confidence in the technology grows, bolstered by continuing advancements and proven reliability, FRP profiles will undoubtedly continue to shape the future of construction and engineering industries. The commitment of manufacturers to quality and innovation, combined with the proven success of these materials in the field, sets a high standard that establishes FRP profiles as an indispensable resource for sustainable and efficient construction practices.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024