loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 15, 2025 09:13

Back to list

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

FRP protruded grating stands out as a versatile and robust material choice that has gained significant traction in various industries due to its unique properties and applications. This fiberglass reinforced plastic (FRP) material offers a reliable alternative to traditional materials like steel or aluminum, emphasizing a commitment to safety, efficiency, and longevity.

The ease of installation and customization of FRP protruded grating cannot be overstated. Its adaptability allows for easy cutting and modification on-site without compromising its structural integrity. This flexibility enables custom solutions tailored to specific industrial or architectural needs, proving essential in complex projects with unique requirements. Beyond its practical benefits, the environmental footprint of FRP protruded grating is notably smaller compared to traditional materials. Its production and lifecycle involve less energy consumption, and since the material is long-lasting, it does not require frequent replacement. This aligns with the growing industry trend towards more sustainable practices and materials. In conclusion, FRP protruded grating exemplifies a product engineered to meet the rising demands for strong, safe, versatile, and sustainable material solutions across various industries. Its inherent properties of strength, corrosion resistance, non-conductivity, and environmental efficiency underscore its growing popularity and reliability. By integrating FRP protruded grating into your infrastructure, you are investing in a future-proof solution that harmonizes safety, performance, and sustainability.

The ease of installation and customization of FRP protruded grating cannot be overstated. Its adaptability allows for easy cutting and modification on-site without compromising its structural integrity. This flexibility enables custom solutions tailored to specific industrial or architectural needs, proving essential in complex projects with unique requirements. Beyond its practical benefits, the environmental footprint of FRP protruded grating is notably smaller compared to traditional materials. Its production and lifecycle involve less energy consumption, and since the material is long-lasting, it does not require frequent replacement. This aligns with the growing industry trend towards more sustainable practices and materials. In conclusion, FRP protruded grating exemplifies a product engineered to meet the rising demands for strong, safe, versatile, and sustainable material solutions across various industries. Its inherent properties of strength, corrosion resistance, non-conductivity, and environmental efficiency underscore its growing popularity and reliability. By integrating FRP protruded grating into your infrastructure, you are investing in a future-proof solution that harmonizes safety, performance, and sustainability.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

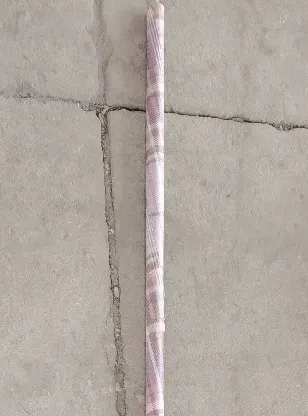

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

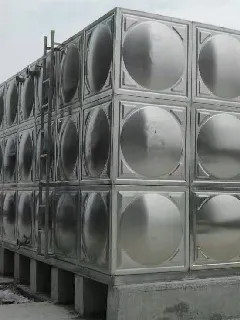

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024