loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

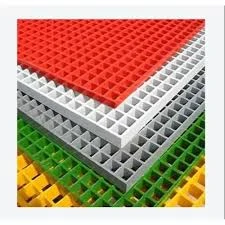

frp pultruded gratings

The Advantages and Applications of FRP Pultruded Gratings

FRP (Fiber Reinforced Polymer) pultruded gratings have gained significant popularity in various industries due to their unique properties and versatility. They are engineered composite materials that incorporate fiberglass reinforcement within a polymer matrix, resulting in a lightweight yet exceptionally strong product. In this article, we will explore the advantages and applications of FRP pultruded gratings.

Key Advantages of FRP Pultruded Gratings

1. Corrosion Resistance One of the standout features of FRP gratings is their resistance to corrosion. Unlike traditional metal gratings, which can rust and degrade over time when exposed to harsh chemicals or wet environments, FRP materials are chemically inert. This quality makes them ideal for use in chemical processing plants, wastewater treatment facilities, and marine environments.

2. Lightweight FRP gratings are significantly lighter than steel or aluminum alternatives. This attribute not only reduces transportation and installation costs but also allows for easier handling and installation. Workers can manage these gratings without heavy lifting equipment, making them suitable for applications where weight is a concern.

3. High Strength-to-Weight Ratio Despite their lightness, FRP gratings boast a high strength-to-weight ratio. They can support heavy loads, making them suitable for industrial applications where robust materials are necessary without adding excessive weight to structures.

4. Non-Conductive Properties FRP pultruded gratings are non-conductive, meaning they do not conduct electricity. This characteristic makes them an excellent choice for environments where electrical safety is paramount, such as in power generation facilities or areas with high electrical hazards.

5. Low Maintenance FRP gratings require minimal maintenance compared to their metal counterparts. They do not need regular painting or treatment to prevent rust or corrosion. This feature not only saves costs but also reduces downtime in industrial processes.

frp pultruded gratings

Applications of FRP Pultruded Gratings

1. Industrial Flooring FRP gratings are widely used in various industrial settings, including factories, plants, and warehouses. Their robust nature makes them suitable for walkways, platforms, and mezzanines, where safety and durability are crucial.

2. Platform Walkways In environments that are prone to spillages or heavy foot traffic, FRP gratings provide safe walking surfaces. They offer excellent slip resistance, reducing the risk of accidents in workplaces.

3. Marine Applications Given their resistance to saltwater and other corrosive substances, FRP gratings are extensively used in boat docks, pier walkways, and other marine structures. They withstand harsh marine conditions while maintaining structural integrity over time.

4. Wastewater Treatment Facilities The adaptability of FRP gratings makes them ideal for use in wastewater treatment plants. Their corrosion resistance and ease of cleaning make them suitable for environments exposed to harsh chemicals and biological materials.

5. Power Plants The non-conductive property of FRP gratings makes them suitable for use in power generation facilities. They provide safe access to equipment while minimizing the risk of electrical hazards.

Conclusion

In conclusion, FRP pultruded gratings offer a multitude of benefits, making them an excellent choice for various applications across different industries. Their corrosion resistance, lightweight nature, high strength-to-weight ratio, non-conductive properties, and low maintenance requirements position them as a superior alternative to traditional materials. As industries continue to seek innovative and safe solutions, the use of FRP gratings is expected to grow, further cementing their role as a vital component in modern infrastructure.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024