loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

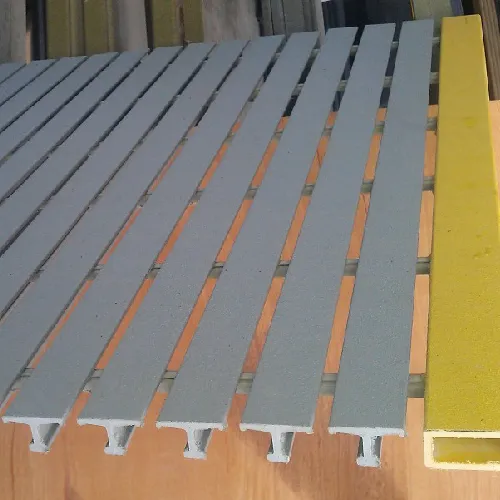

frp pultruded profiles

An Overview of FRP Pultruded Profiles Applications and Advantages

Fiber Reinforced Polymer (FRP) pultruded profiles have become increasingly popular in various industries due to their unique properties and versatility. The pultrusion process involves the continuous shaping of composite materials, which are primarily made up of a resin matrix reinforced with fibers such as glass, carbon, or aramid. This article delves into the characteristics, applications, and advantages of FRP pultruded profiles.

Understanding FRP Pultruded Profiles

Pultrusion is a manufacturing process that allows for the continuous production of composite materials with consistent cross-section shapes. In this process, fibers are drawn through a resin bath and then pulled through a heated die. The combination of heat and pressure helps the resin cure, creating a strong, rigid profile. The resulting FRP pultruded profiles are lightweight, durable, and resistant to various environmental factors.

One of the most significant characteristics of FRP pultruded profiles is their high strength-to-weight ratio. This property makes them appealing for applications where reducing weight without compromising strength is essential. Additionally, these profiles exhibit excellent corrosion resistance, making them suitable for use in harsh environments such as chemical processing plants, marine applications, and coastal infrastructure.

Applications of FRP Pultruded Profiles

The versatility of FRP pultruded profiles allows them to find applications in numerous sectors

1. Construction and Infrastructure FRP profiles are extensively used in building construction, bridges, walkways, and other infrastructure due to their high strength, lightweight nature, and resistance to deterioration. They can replace traditional materials like steel and concrete, especially in environments prone to corrosion.

2. Electrical and Telecommunications The insulating properties of FRP make it an excellent choice for supporting structures in electrical applications. FRP poles and supports are used in telecommunications to reduce signal interference and withstand harsh weather conditions.

3. Transportation In the transportation sector, FRP pultruded profiles are utilized in manufacturing components for vehicles, trailers, and aircraft. Their lightweight nature contributes to improved fuel efficiency and performance.

4. Marine Applications Due to their resistance to saltwater corrosion, FRP profiles are commonly used in the marine industry for boat manufacturing, docks, and marinas. These materials enhance durability while minimizing maintenance costs.

frp pultruded profiles

5. Water and Wastewater Treatment FRP profiles are used in applications involving water and wastewater treatment facilities. Their resistance to chemicals and moisture makes them suitable for constructing tanks, pipes, and other infrastructure components.

Advantages of Using FRP Pultruded Profiles

The adoption of FRP pultruded profiles offers many benefits

- Durability FRP materials exhibit a long lifespan and are resistant to environmental degradation. They do not rust or corrode, contributing to lower maintenance costs and longer service life.

- Lightweight FRP profiles are significantly lighter than traditional materials, allowing for easier handling and installation. This lightweight property can also lead to cost savings in transportation and structural support.

- Versatility in Design The pultrusion process enables the fabrication of profiles in various shapes and sizes, allowing for innovative designs tailored to specific requirements.

- Sustainability Many FRP materials can be produced from recycled components or designed for recyclability, aligning with growing environmental concerns and sustainability initiatives.

- Thermal Insulation The insulating properties of FRP prevent heat transfer, making them an ideal choice for applications requiring temperature control.

Conclusion

In conclusion, FRP pultruded profiles present a robust solution across diverse applications, thanks to their unique characteristics and advantages. As industries continue to seek innovative materials that combine performance with sustainability, the demand for FRP pultruded profiles is expected to rise. With ongoing advancements in composite material technology, the future looks bright for these versatile profiles, promising to play a pivotal role in shaping modern infrastructure and applications.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024