loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

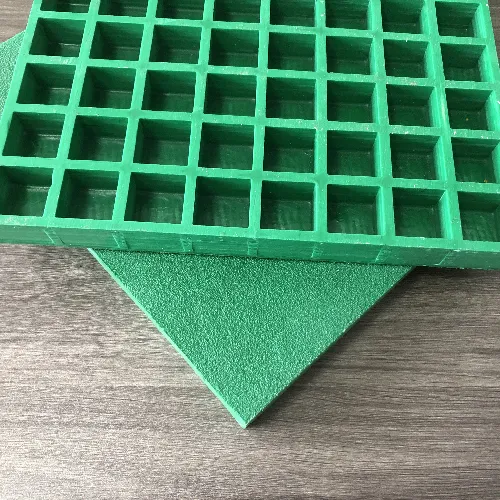

frp pultruded profiles

Understanding FRP Pultruded Profiles A Comprehensive Overview

Fiber Reinforced Plastic (FRP) pultruded profiles have gained prominence in various industries due to their unique properties and advantages. These profiles are manufactured through a continuous process that combines fibers and resins, creating a lightweight, strong, and corrosion-resistant material. In this article, we will delve into the characteristics, benefits, and applications of FRP pultruded profiles, illuminating why they are becoming the material of choice in numerous sectors.

What are FRP Pultruded Profiles?

FRP pultruded profiles are composite materials made from fibers, typically glass or carbon, and thermosetting resins such as polyester or epoxy. The pultrusion process involves drawing these materials through a heated die, where the resin cures, resulting in solid profiles with consistent shapes and dimensions. This method ensures that the fibers are aligned in the direction of maximum load, maximizing their strength and stiffness.

Key Characteristics

1. Lightweight One of the most significant advantages of FRP pultruded profiles is their lightweight nature. This quality translates to ease of handling and installation, leading to reduced labor costs and faster project completion.

2. Corrosion Resistance Unlike traditional materials like steel or aluminum, FRP profiles do not corrode when exposed to harsh environmental conditions, including chemicals, moisture, and UV rays. This makes them ideal for use in marine applications and chemical processing industries.

3. High Strength and Stiffness FRP profiles exhibit excellent mechanical properties, providing high strength-to-weight ratios. They can withstand substantial loads and stress without deforming, making them suitable for structural applications.

frp pultruded profiles

4. Thermal and Electrical Insulation These profiles are poor conductors of heat and electricity, making them ideal for applications where insulation is a priority, such as in electrical enclosures and structural components in power plants.

Applications

FRP pultruded profiles are versatile and find applications across various industries, including

- Construction Used for reinforcing structures, building frameworks, and scaffolding due to their strength and resistance to environmental degradation. - Transportation Applied in manufacturing lightweight vehicle components, reducing overall vehicle weight and improving fuel efficiency.

- Marine Ideal for boat building, dock components, and other applications where exposure to water and chemicals is a concern.

- Electrical Utilized in electrical grids and communication towers for their insulating properties and corrosion resistance.

Conclusion

As industries continually seek materials that offer durability, strength, and environmental resistance, FRP pultruded profiles stand out as an innovative solution. Their application not only enhances the longevity of structures and components but also offers substantial economic benefits. The trend towards sustainable practices in manufacturing and construction further emphasizes the importance of materials like FRP, which contribute to both efficiency and environmental stewardship. As technology advances, we can expect to see even broader utilization of FRP pultruded profiles, highlighting their significance in the modern industrial landscape.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024