loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovations in FRP Pultruded Section Design and Applications for Structural Engineering

Understanding FRP Pultruded Sections Applications and Benefits

In the world of modern engineering and construction, the demand for lightweight, durable, and corrosion-resistant materials is steadily increasing. One of the standout solutions in this realm is Fiberglass Reinforced Polymer (FRP) pultruded sections. This article will explore what FRP pultruded sections are, their manufacturing process, applications, and the myriad benefits they offer compared to traditional materials.

What are FRP Pultruded Sections?

FRP pultruded sections are composite materials made from a combination of fiberglass and resin. The pultrusion process entails drawing continuous strands of fiberglass through a resin bath and then through a heated metal die, where it cures and hardens into specific shapes. This method allows for the production of various profiles, including beams, channels, angles, and more, which can be tailored to specific application requirements.

Manufacturing Process

The pultrusion process is notable for its efficiency and capability to produce complex shapes in a continuous manner. The primary steps involved include

1. Material Preparation Continuous strands of fiberglass reinforcement are aligned and combined with thermosetting resin (typically epoxy, polyester, or vinyl ester).

2. Impregnation The fiberglass is passed through a resin bath, where it becomes thoroughly saturated with resin.

3. Shaping The saturated fiberglass is then pulled through a heated die. The heat causes the resin to cure, solidifying the shape into a strong and rigid profile.

4. Cutting Once cured, the continuous profile is cut into specified lengths according to project requirements.

This production method yields materials that have uniform properties, high strength, and lightweight characteristics, making them suitable for various environments and conditions.

Applications

FRP pultruded sections find application across numerous industries. Some prominent sectors include

1. Construction In structural applications, FRP pultruded sections are used for beams, columns, and decking, contributing to reduced overall building weight without compromising strength.

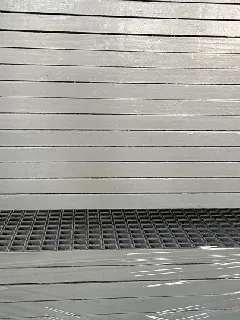

frp pultruded sections

2. Infrastructure Bridges, walkways, and railings made from FRP benefit from their corrosion resistance, reducing maintenance costs and increasing longevity.

4. Chemical Industries FRP's resistance to harmful chemicals makes it ideal for the construction of tanks, pipelines, and other equipment in chemical processing plants.

5. Electrical FRP is also employed in the manufacture of electrical components, such as poles and supports, due to its non-conductive nature.

Benefits of FRP Pultruded Sections

1. Corrosion Resistance One of the primary advantages of FRP is its exceptional resistance to corrosion, ensuring longevity in harsh environments.

2. Lightweight FRP pultruded sections are much lighter than traditional materials like steel or concrete, making them easier and cheaper to transport and install.

3. High Strength-to-Weight Ratio Despite being lightweight, FRP materials offer comparable, if not superior, structural integrity and load-bearing capabilities.

4. Low Maintenance The inherent properties of FRP reduce the need for routine maintenance and inspections, leading to lower life-cycle costs.

5. Design Flexibility The pultrusion process allows for a broad range of shapes and sizes, catering to specific design requirements and applications.

6. Sustainability Many FRP materials are manufactured with recyclable components, contributing to more sustainable building practices.

Conclusion

FRP pultruded sections represent a significant advancement in material technology, providing engineers and architects with advantages that traditional materials cannot match. Their versatility, combined with superior performance characteristics, positions them as a preferred choice for modern infrastructure and construction projects. As industries continue to evolve, the role of FRP in achieving sustainable and durable solutions will only become more critical. With continued innovations in this field,FRP pultruded sections are set to pave the way for a more resilient and efficient future in construction and engineering.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024