loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

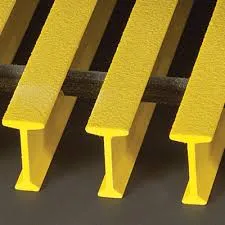

frp pultruded sections

The Advantages of FRP Pultruded Sections in Modern Construction

As the construction industry continues to seek innovative materials that enhance performance while minimizing environmental impact, Fiber Reinforced Polymer (FRP) pultruded sections have emerged as a leading solution. These composite materials, made from a combination of fiberglass and resin, offer a range of benefits that make them increasingly popular in structural applications. This article explores what FRP pultruded sections are and highlights their advantages in various construction contexts.

Understanding FRP Pultruded Sections

FRP pultruded sections are created through a continuous manufacturing process called pultrusion. In this process, continuous strands of fiberglass roving are saturated with a polymer resin and then pulled through a heated die. This not only shapes the material to the desired profile—such as beams, rods, or panels—but also cures it into a solid state. The result is a lightweight, high-strength material that exhibits excellent durability and resistance to environmental factors.

Lightweight and High Strength

One of the most significant advantages of FRP pultruded sections is their impressive strength-to-weight ratio. Compared to traditional materials like steel or wood, FRP is considerably lighter, which facilitates easier handling and installation. This feature is particularly beneficial in projects where weight constraints are critical, such as in bridge construction or when reinforcing existing structures.

Corrosion Resistance

Another critical advantage of FRP pultruded sections is their exceptional resistance to corrosion. Unlike steel, which can rust and degrade when exposed to moisture and chemicals, FRP composites do not corrode. This property makes them ideal for applications in harsh environments, including marine settings, chemical plants, and wastewater treatment facilities. The longevity of FRP materials not only reduces maintenance costs but also extends the lifespan of structures.

Design Flexibility

frp pultruded sections

FRP pultruded sections offer significant design flexibility thanks to their customizable profiles and colors. Architects and engineers can specify unique shapes and sizes that meet the functional and aesthetic requirements of their projects. This adaptability allows for innovative designs that may be challenging to achieve with traditional materials, making FRP a preferred choice for modern architectural applications.

Thermal and Electrical Insulation

Another compelling feature of FRP is its thermal and electrical insulation properties. This characteristic is especially useful in environments where thermal conductivity could lead to energy loss or safety hazards. Buildings that use FRP pultruded sections can benefit from enhanced energy efficiency and reduced risk of electrical accidents.

Sustainability

The growing emphasis on sustainability in construction makes FRP an appealing option. The production of FRP pultruded sections generally consumes fewer resources than traditional building materials. Additionally, many FRP products can be manufactured using recycled materials, and their durability contributes to reduced waste over time. These factors align with global efforts to create more sustainable building practices.

Applications in Various Industries

FRP pultruded sections have found applications across various industries, including transportation, construction, and telecommunications. They are utilized in pedestrian walkways, bridge components, structural support systems, and even in the construction of wind turbine blades. The versatility of FRP materials makes them suitable for a wide range of applications, ensuring that they meet the demanding needs of modern engineering projects.

Conclusion

In summary, FRP pultruded sections represent a significant advancement in construction materials, combining lightweight properties with high strength, corrosion resistance, design flexibility, and sustainability. As the industry continues to embrace innovative building solutions, FRP is poised to play a pivotal role in shaping the future of construction. By leveraging the benefits of FRP pultruded sections, engineers and designers can create structures that are not only more efficient but also more resilient and environmentally friendly.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024