loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 17, 2025 17:51

Back to list

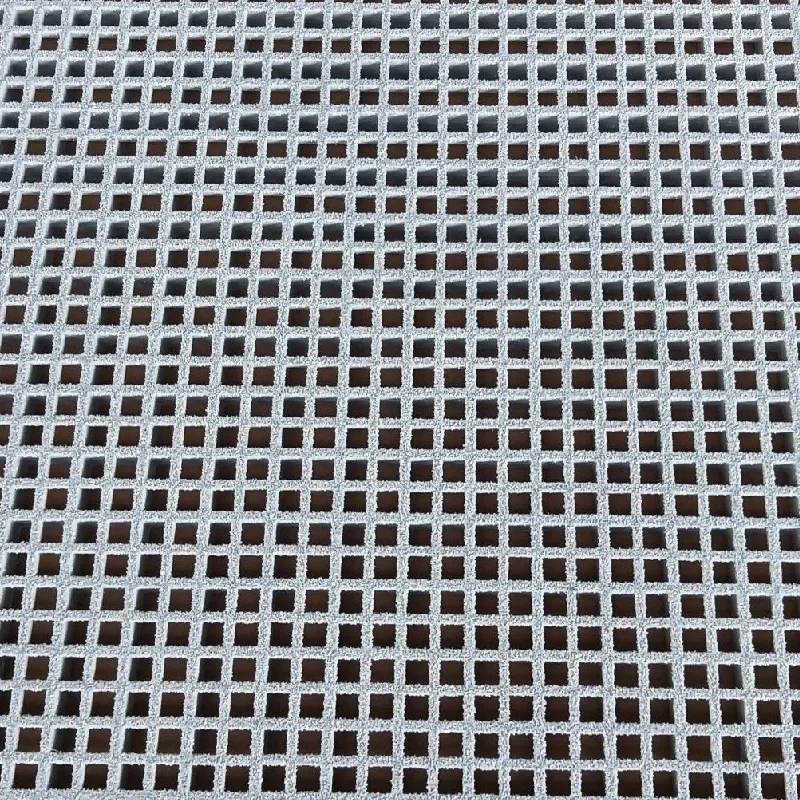

frp railing

In today's rapidly evolving industrial landscape, choosing the right materials for construction and safety purposes is paramount. Fiberglass Reinforced Plastic (FRP) railings have emerged as a popular choice due to their exceptional blend of durability, minimal maintenance, and resistance to environmental factors. This article delves into the nuances of FRP railings, drawing attention to their expansive benefits and proving why they hold a supreme position in the market.

From an aesthetic standpoint, FRP railings provide flexibility that traditional materials cannot match. They are available in a multitude of colors and finishes, offering architects and designers the liberty to match the aesthetics of any project. Unlike metal railings, which require periodic painting or finishing to maintain appearance, FRP's color is molded into the part, ensuring a long-lasting, fade-resistant finish. This characteristic not only cuts down on maintenance efforts but also ensures that the installations remain attractive over time. Trust is rooted in the proven track record of FRP railings in numerous high-stakes applications. Industries such as oil and gas, marine, and telecommunications have trusted FRP products for their reliability and performance. Case studies and testimonials from these sectors provide ample evidence of FRP railing systems' long-lasting impact and trustworthiness. Many leading manufacturers also offer extensive warranties, further cementing consumer confidence in their investments. However, when considering FRP railings, it's essential to work with manufacturers who understand the complexities involved in their production and application. A reputable provider ensures that the FRP composites are manufactured to meet rigorous industry standards, guaranteeing safety and performance. Look for companies that have certifications and compliance with international standards such as ISO 9001 and ASTM, which serve as indicators of quality assurance. In conclusion, FRP railings present a plethora of advantages that make them an exemplary choice for modern construction demands. Their durability, low maintenance, and adaptability to harsh environments, combined with long-term cost efficiencies, underscore their growing popularity and trust within the industry. As companies continue to seek sustainable and innovative solutions, FRP railings cement themselves as leaders, showcasing their unmatched performance, safety, and aesthetic appeal.

From an aesthetic standpoint, FRP railings provide flexibility that traditional materials cannot match. They are available in a multitude of colors and finishes, offering architects and designers the liberty to match the aesthetics of any project. Unlike metal railings, which require periodic painting or finishing to maintain appearance, FRP's color is molded into the part, ensuring a long-lasting, fade-resistant finish. This characteristic not only cuts down on maintenance efforts but also ensures that the installations remain attractive over time. Trust is rooted in the proven track record of FRP railings in numerous high-stakes applications. Industries such as oil and gas, marine, and telecommunications have trusted FRP products for their reliability and performance. Case studies and testimonials from these sectors provide ample evidence of FRP railing systems' long-lasting impact and trustworthiness. Many leading manufacturers also offer extensive warranties, further cementing consumer confidence in their investments. However, when considering FRP railings, it's essential to work with manufacturers who understand the complexities involved in their production and application. A reputable provider ensures that the FRP composites are manufactured to meet rigorous industry standards, guaranteeing safety and performance. Look for companies that have certifications and compliance with international standards such as ISO 9001 and ASTM, which serve as indicators of quality assurance. In conclusion, FRP railings present a plethora of advantages that make them an exemplary choice for modern construction demands. Their durability, low maintenance, and adaptability to harsh environments, combined with long-term cost efficiencies, underscore their growing popularity and trust within the industry. As companies continue to seek sustainable and innovative solutions, FRP railings cement themselves as leaders, showcasing their unmatched performance, safety, and aesthetic appeal.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024