loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 03, 2025 04:59

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

In the realm of construction and civil engineering, Fiberglass Reinforced Polymer (FRP) rebar is gaining considerable traction due to its intrinsic advantages over traditional materials like steel. For anyone keeping an eye on market dynamics or engaging in procurement, understanding the pricing landscape of FRP rebar is vital. This article delves into the factors influencing FRP rebar prices, offering a comprehensive guide drawn from field expertise and authoritative sources.

5. Global Economic Factors Exchange rates and global economic conditions can impact the price of both imported raw materials and finished products. For projects relying on international supply chains, such fluctuations can result in varying budget expectations. 6. Regulatory Environment Compliance with international and domestic standards can influence FRP rebar prices. Requirements for certifications or adherence to strict environmental guidelines may increase production expenses, thus affecting the pricing structure. From a practical standpoint, pricing strategies in the FRP rebar sector often balance between capturing competitive market share and covering the costs related to innovation and compliance. Buyers and procurement specialists need to stay abreast of not only the immediate cost but also the lifecycle cost benefits that FRP rebars present compared to traditional materials. In terms of market strategies, companies are innovating organoleptically appealing narratives around their products, emphasizing the total cost of ownership benefits. They are also partnering with renowned engineering firms and leveraging brand authority to instill confidence in prospective buyers. Trustworthiness in pricing is enhanced when suppliers provide transparent cost breakdowns and thorough product performance data. Engaging with the right suppliers can reveal not just price-related insights but also information about product innovations and applications, fostering an environment where expert knowledge drives procurement decisions. Conclusively, while the upfront investment in FRP rebar might appear higher than traditional steel, the long-term benefits like reduced maintenance costs, longevity, and superior performance in harsh environments make it a strategic choice for future-oriented constructions. A comprehensive understanding of the factors affecting FRP rebar prices enables better decision-making, positioning stakeholders to leverage the material's benefits fully and strategically align with evolving market trends.

5. Global Economic Factors Exchange rates and global economic conditions can impact the price of both imported raw materials and finished products. For projects relying on international supply chains, such fluctuations can result in varying budget expectations. 6. Regulatory Environment Compliance with international and domestic standards can influence FRP rebar prices. Requirements for certifications or adherence to strict environmental guidelines may increase production expenses, thus affecting the pricing structure. From a practical standpoint, pricing strategies in the FRP rebar sector often balance between capturing competitive market share and covering the costs related to innovation and compliance. Buyers and procurement specialists need to stay abreast of not only the immediate cost but also the lifecycle cost benefits that FRP rebars present compared to traditional materials. In terms of market strategies, companies are innovating organoleptically appealing narratives around their products, emphasizing the total cost of ownership benefits. They are also partnering with renowned engineering firms and leveraging brand authority to instill confidence in prospective buyers. Trustworthiness in pricing is enhanced when suppliers provide transparent cost breakdowns and thorough product performance data. Engaging with the right suppliers can reveal not just price-related insights but also information about product innovations and applications, fostering an environment where expert knowledge drives procurement decisions. Conclusively, while the upfront investment in FRP rebar might appear higher than traditional steel, the long-term benefits like reduced maintenance costs, longevity, and superior performance in harsh environments make it a strategic choice for future-oriented constructions. A comprehensive understanding of the factors affecting FRP rebar prices enables better decision-making, positioning stakeholders to leverage the material's benefits fully and strategically align with evolving market trends.

Share

Latest news

-

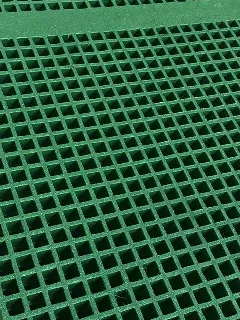

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024