loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Properties and Applications of FRP Rectangular Tubes in Engineering Design

Understanding FRP Rectangular Tubes A Modern Construction Solution

Fiber Reinforced Polymer (FRP) rectangular tubes are gaining popularity in various construction and engineering applications due to their outstanding mechanical properties, lightweight nature, and resistance to environmental factors. This composite material, made from a polymer matrix reinforced with fibers, typically glass, carbon, or aramid, offers significant advantages over traditional materials like steel and concrete.

Composition and Manufacturing

FRP rectangular tubes are manufactured through processes such as pultrusion, where continuous fibers are drawn through a resin bath and then cured in a heated die to form the desired shape. This method ensures uniformity, high strength, and low weight. The tubes can be tailored to specific requirements by altering the fiber orientation and matrix composition, making them versatile for various applications.

Mechanical Properties

One of the most compelling reasons to use FRP rectangular tubes is their impressive mechanical properties. They exhibit high tensile strength, which is essential for load-bearing applications. Additionally, FRP materials are relatively lightweight compared to traditional materials, making transportation and installation more efficient. For example, an FRP tube can weigh significantly less than an equivalent steel tube, reducing overall project costs and enhancing ease of handling.

The stiffness of FRP rectangular tubes varies based on the type and orientation of the reinforcing fibers used. This allows engineers to customize the stiffness of the material to meet specific structural requirements. Moreover, FRP is resistant to corrosion, which is particularly beneficial in environments exposed to chemicals, moisture, or saltwater.

Environmental Resistance

One of the standout features of FRP materials, including rectangular tubes, is their resistance to environmental degradation. Unlike metals that can rust or corrode, FRP tubes maintain their structural integrity over time. This quality makes them ideal for applications in harsh environments, such as marine structures, bridges, and chemical plants.

Moreover, FRP materials do not suffer from temperature-related expansion or contraction to the same extent as metals do, providing consistent performance across varying temperature ranges. This characteristic allows for reliable long-term performance, reducing the need for frequent maintenance or replacements.

frp rectangular tube

Applications

The versatility of FRP rectangular tubes has led to their widespread use across different industries. Some notable applications include

1. Construction and Infrastructure FRP tubes are used in bridges, railings, and building frames. Their lightweight nature allows for easy installation, and their resistance to corrosion prolongs the lifecycle of structures.

2. Marine Applications Due to their resistance to saltwater and other corrosive agents, FRP rectangular tubes are commonly used in marinas, docks, and ships. They help reduce the overall weight of vessels while maintaining structural integrity.

3. Automotive and Aerospace Industries In these sectors, weight reduction is critical for enhancing fuel efficiency. FRP rectangular tubes are integrated into various components, contributing to lighter and more fuel-efficient vehicles.

4. Sports Equipment and Recreational Vehicles The high strength-to-weight ratio makes FRP ideal for bicycles, skateboards, and other sporting goods. They provide both durability and performance without compromising weight.

Conclusion

FRP rectangular tubes represent a cutting-edge solution in modern construction and engineering. Their unique combination of strength, lightweight nature, and environmental resistance makes them an attractive alternative to traditional materials. As technology continues to evolve, we can expect to see an even wider range of applications for FRP in various fields, driving innovation and improving efficiency in structural design. The adoption of FRP materials not only enhances performance but also contributes to sustainable practices by reducing the overall environmental impact of construction projects.

In summary, FRP rectangular tubes stand out as a contemporary material option that meets the demands of today’s engineering challenges, making them a vital component of future infrastructure development. Their unique properties promise to shape the future of construction and design in unprecedented ways.

-

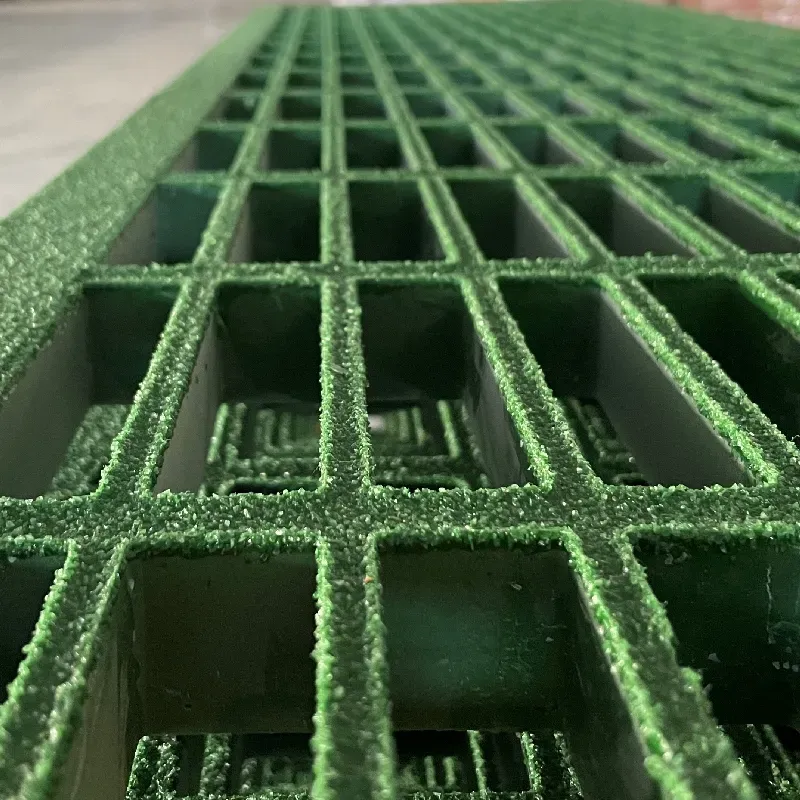

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024