loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp rectangular tube

Understanding FRP Rectangular Tubes Properties and Applications

Fiber Reinforced Polymer (FRP) materials have gained significant traction in various industries due to their exceptional mechanical properties, lightweight nature, and corrosion resistance. Among the different shapes and forms that FRP can take, rectangular tubes are particularly popular due to their versatility and structural efficiency. This article delves into the characteristics, manufacturing processes, applications, and advantages of FRP rectangular tubes.

What are FRP Rectangular Tubes?

FRP rectangular tubes are composite structures made primarily of a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. The rectangular cross-section offers higher moment of inertia compared to circular tubes, making them an excellent choice for structural applications requiring increased stiffness and strength. The tubes can be manufactured in various sizes and thicknesses, catering to specific requirements across different sectors.

Properties of FRP Rectangular Tubes

1. Lightweight One of the standout features of FRP materials is their low density. FRP rectangular tubes are much lighter than traditional materials like steel or aluminum, making them easier to transport and install.

2. Corrosion Resistance FRP is inherently resistant to moisture, chemicals, and environmental degradation, which significantly extends the service life of components made from these materials, especially in outdoor and harsh environments.

3. High Strength-to-Weight Ratio The reinforcement provided by fibers gives FRP rectangular tubes a very high strength-to-weight ratio. This allows for the design of structures that are both lightweight and robust, meeting the demands of various engineering applications.

4. Thermal and Electrical Insulation FRP materials are excellent insulators and do not conduct electricity. This characteristic can be particularly beneficial in applications where electrical insulation is imperative.

5. Design Flexibility The manufacturing processes for FRP allow for a wide range of shapes, sizes, and configurations, enabling engineers and designers to create components tailored to specific needs.

Manufacturing Process

The production of FRP rectangular tubes encompasses several key methods, including

- Pultrusion This is one of the most common methods for producing FRP profiles. In pultrusion, continuous fiber reinforcement is pulled through a resin bath and then into a heated die where it is cured. This process allows for mass production of uniform rectangular tubes.

- Filament Winding This technique involves winding resin-coated fibers around a mandrel. After winding, the assembly is cured to set the resin, resulting in strong and lightweight structures.

frp rectangular tube

- Lay-Up In the lay-up method, layers of fiber and resin are manually arranged and cured. Although this method is less efficient for mass production, it allows for the creation of complex shapes.

Applications of FRP Rectangular Tubes

FRP rectangular tubes find applications in various sectors, including

- Construction Used in building frameworks, bridges, and other structural components due to their strength and durability.

- Transportation Employed in the manufacturing of lightweight vehicle components, which contribute to improved fuel efficiency.

- Electrical and Telecommunications Utilized for poles, supports, and other infrastructure where electrical and environmental insulation is required.

- Marine Industry Commonly used in boat building and marine structures because of their resistance to saltwater and other corrosive environments.

- Aerospace In aviation, FRP rectangular tubes are leveraged for parts that require a robust structural integrity with minimal weight.

Advantages Over Traditional Materials

While there are many materials available for engineering applications, FRP rectangular tubes present clear advantages

- Cost-Effectiveness Although the initial cost may be higher, the long-term savings on maintenance and replacement costs due to durability and corrosion resistance make FRP an economically viable option.

- Sustainability FRP materials often have a lower environmental impact during their lifecycle compared to metal materials that require intensive mining and refined processes.

In conclusion, FRP rectangular tubes offer an innovative solution for complex structural needs across various industries. With their remarkable properties, versatile applications, and the ability to significantly reduce weight while maintaining strength, they are a prime choice for modern engineering challenges. As technology advances, we can anticipate even broader applications and innovation in the realm of FRP materials.

-

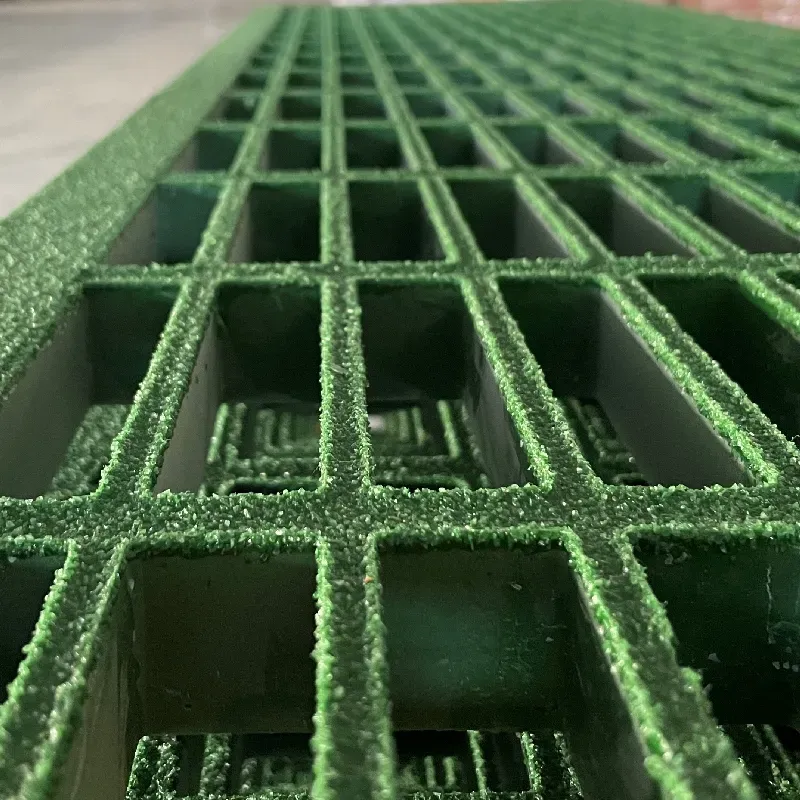

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024