loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Competitive Pricing for Fiberglass Reinforced Plastic Rods in Bulk

Understanding the Pricing of FRP Rods A Comprehensive Overview

Fiber Reinforced Polymer (FRP) rods have emerged as a revolutionary material in various industries, especially in construction and infrastructure. Their unique properties — such as corrosion resistance, high strength-to-weight ratio, and durability — make them increasingly popular for applications ranging from reinforcing concrete structures to serving as a lightweight alternative to traditional steel reinforcement. However, the pricing of FRP rods varies widely based on several factors, and understanding these can help consumers make informed decisions.

Factors Influencing FRP Rod Prices

Understanding the Pricing of FRP Rods A Comprehensive Overview

2. Manufacturing Process The method of production plays a crucial role in determining the price of FRP rods. Techniques such as pultrusion, filament winding, and resin transfer molding have distinct costs associated with them. Pultrusion, a method where fibers are pulled through a resin bath and then through a heated die, is often more cost-effective for producing high volumes, thus resulting in lower prices for consumers. In contrast, more complex processes like filament winding may require significant labor and time, leading to higher costs.

frp rod price

3. Diameter and Length The size of the FRP rods also influences pricing. Larger diameter rods and longer lengths typically incur higher costs due to the increased amount of raw materials required for production. Custom sizes may also impact pricing, as specialized equipment and processes may be needed to fabricate non-standard dimensions.

4. Market Demand Like any commodity, the price of FRP rods is subject to market fluctuations driven by supply and demand dynamics. If there is a significant demand surge in construction projects or infrastructural developments, prices can rise accordingly. Conversely, in times of economic downturn, demand may decrease, leading to potential price drops.

5. Geographical Factors The location of production and transportation costs can also affect pricing. Regions with established manufacturing facilities may offer lower prices due to reduced shipping and handling costs, while remote areas might experience higher prices due to logistical challenges.

Conclusion

In summary, the price of FRP rods can vary widely based on material composition, manufacturing processes, size, market demand, and geographical factors. Consumers should carefully assess their project requirements and consult with suppliers to understand the nuances of pricing within the context of their specific needs. As technology advances and production techniques improve, the market for FRP rods will likely evolve, potentially leading to more competitive pricing and wider adoption across various sectors. Whether for construction, automotive, or aerospace applications, FRP rods provide a promising solution that balances performance with cost-effectiveness.

-

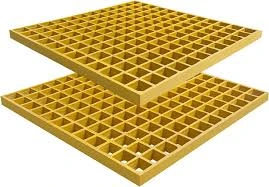

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024